Air Washer System and Dispensing Booth for Pharmaceutical Industry: Ensuring Clean and Controlled Environments

the Air Washer System and the Dispensing Booth for Pharmaceutical applications.

In the pharmaceutical industry, maintaining a controlled environment free from contaminants is essential to ensure product quality, safety, and compliance with regulatory standards. Key to achieving these goals are two critical components: the Air Washer System and the Dispensing Booth for Pharmaceutical applications. Both systems play a pivotal role in maintaining optimal air quality, controlling particulate matter, and ensuring a contamination-free space during the manufacturing, packaging, and dispensing of pharmaceutical products. Let’s explore the significance of these systems and how they contribute to the success of pharmaceutical operations.

The Role of Air Washer System in Pharmaceutical Manufacturing

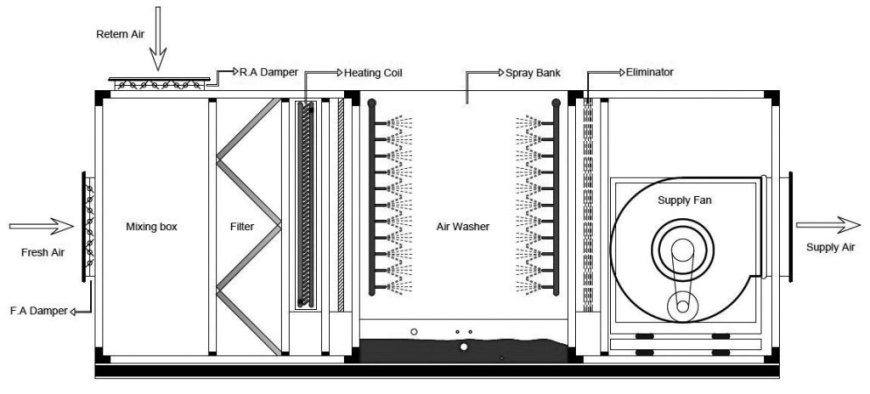

An Air Washer System is an advanced air filtration and purification technology used to maintain optimal air quality by removing dust, particles, and other airborne contaminants from the air. The system functions by using water or other filtration media to wash and clean the air, ensuring it meets the required standards for cleanliness and humidity levels.

In pharmaceutical manufacturing, an Air Washer System is crucial for several reasons:

-

Particle Removal: The air in a pharmaceutical facility can carry harmful dust, bacteria, and other contaminants. An Air Washer System ensures that the air circulating in sensitive areas, such as clean rooms and laboratories, remains free from particles that could compromise product integrity or contaminate sterile environments.

-

Humidity Control: Maintaining precise humidity levels is essential in pharmaceutical production, as high humidity can lead to the growth of mold, while low humidity may affect the stability of products. The Air Washer System helps to regulate and maintain appropriate humidity levels, ensuring that the environment remains stable and conducive to the production process.

-

Energy Efficiency: The Air Washer System can reduce the need for separate air conditioning and humidification systems, resulting in lower energy consumption. This efficiency is particularly important in the pharmaceutical industry, where consistent environmental control is critical for production but should also be done in a cost-effective manner.

-

Regulatory Compliance: Pharmaceutical companies must adhere to strict cleanliness standards as per regulatory guidelines. An Air Washer System helps ensure compliance with these regulations by providing clean, contaminant-free air, making it easier for manufacturers to meet health and safety requirements.

The Importance of Dispensing Booth for Pharmaceutical Operations

The Dispensing Booth for Pharmaceutical use is another essential system in maintaining a sterile environment during the critical stages of pharmaceutical production. These booths are designed to protect both the product and the personnel handling potentially hazardous materials.

Key features and benefits of the Dispensing Booth for Pharmaceutical applications include:

-

Controlled Environment: A Dispensing Booth creates a controlled environment that protects pharmaceutical products from contamination during the dispensing process. This is particularly important for handling active pharmaceutical ingredients (APIs) or other sensitive materials that must be weighed, measured, or dispensed under strict conditions.

-

Protecting Personnel: The Dispensing Booth is equipped with ventilation systems to ensure that operators are not exposed to hazardous dust or fumes during the dispensing process. It prevents the inhalation of harmful substances, which is essential for maintaining the health and safety of the workforce.

-

Prevention of Cross-Contamination: Pharmaceutical facilities often handle different batches of products or ingredients simultaneously. A Dispensing Booth helps prevent cross-contamination by isolating the dispensing area and controlling airflow to ensure that different substances do not mix or interact in harmful ways.

-

Enhanced Airflow: The booth's ventilation system is designed to maintain an efficient airflow, preventing the accumulation of hazardous fumes or particles. The system also directs clean air into the booth while exhaust air is safely removed, creating a safe and controlled workspace for operators.

How Syntec Airflow System Supports Pharmaceutical Cleanliness and Safety

To meet the stringent demands of the pharmaceutical industry, it is essential to partner with trusted and reliable system providers. Syntec Airflow System offers innovative Air Washer Systems and Dispensing Booths for Pharmaceutical applications, specifically designed to maintain a clean and safe environment. These systems are built using the latest technologies to ensure that pharmaceutical facilities meet both air quality and regulatory standards.

By incorporating Syntec Airflow System’s solutions, pharmaceutical companies can ensure high levels of air purity, reduced risk of contamination, and compliance with industry regulations, which are critical for successful manufacturing and product safety.

Conclusion

In the pharmaceutical industry, creating and maintaining a sterile, contaminant-free environment is essential for ensuring the production of safe and effective products. The integration of Air Washer Systems and Dispensing Booths for Pharmaceutical applications plays a crucial role in achieving this goal. These systems work together to provide clean, purified air, regulate humidity levels, and ensure that personnel and products remain protected during critical stages of manufacturing and dispensing. By leveraging solutions from Syntec Airflow System, pharmaceutical facilities can maintain the highest levels of cleanliness and efficiency, ensuring their products meet the required safety and regulatory standards.

What's Your Reaction?