Cleanroom Design: The Ultimate Guide to Creating Contamination-Free Environments

Quantum PharmaTech Services specializes in turnkey solutions for Pharmaceutical, Biotech, Herbal, Homeopathy, Cosmetics, and Food industries. We offer expert design, erection, and operation of manufacturing plants, ensuring compliance with national and international regulatory standards. Our innovative approach guarantees timely project execution of any scale or complexity.

In industries like pharmaceuticals, biotechnology, and electronics, maintaining a contamination-free environment is critical. Cleanroom design is the cornerstone of ensuring these environments meet strict cleanliness and safety standards. This blog will take you through the essentials of cleanroom design, focusing on user needs and how Quantum PharmaTech Services delivers exceptional solutions to meet industry requirements.

What is a Cleanroom?

A cleanroom is a controlled environment where pollutants like dust, microbes, and airborne particles are minimized. These spaces are classified based on the number of particles per cubic meter, as defined by ISO standards.

Whether it’s for producing life-saving drugs or precision electronics, cleanrooms play a vital role in safeguarding product integrity and compliance with regulatory standards.

Key Elements of Effective Cleanroom Design

-

Airflow Management

-

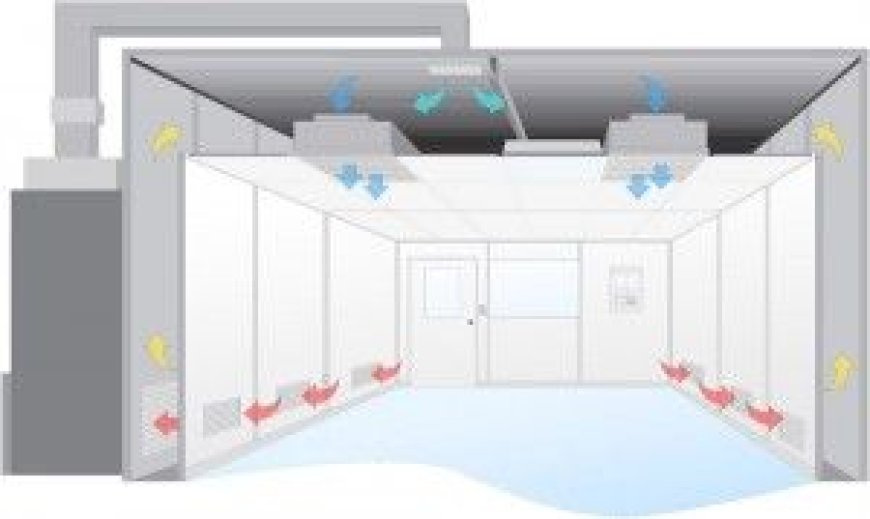

Airflow systems are the backbone of cleanroom functionality. High-Efficiency Particulate Air (HEPA) filters and Ultra-Low Penetration Air (ULPA) filters remove contaminants from the air, maintaining consistent pressure and particle control.

-

-

Zoning and Layout

-

Efficient cleanroom design prioritizes zoning, separating high-risk areas from low-risk zones. This prevents cross-contamination and ensures workflow efficiency.

-

-

Material Selection

-

Walls, ceilings, and floors should be constructed from non-shedding materials that resist microbial growth and are easy to clean.

-

-

HVAC Systems

-

Heating, Ventilation, and Air Conditioning (HVAC) systems control temperature, humidity, and pressure, ensuring a stable and contamination-free environment.

-

-

Personnel Flow

-

Strict protocols for personnel movement, including air showers and gowning rooms, minimize contamination risks.

-

-

Lighting and Ergonomics

-

Proper lighting and ergonomic designs enhance productivity and reduce errors, especially in high-precision tasks.

-

Benefits of a Well-Designed Cleanroom

-

Regulatory Compliance: Meeting ISO, FDA, and GMP standards.

-

Enhanced Productivity: Reducing contamination reduces downtime and increases output.

-

Cost Efficiency: Long-term savings through optimized energy use and minimal maintenance requirements.

-

Product Safety: Ensuring the quality and reliability of end products.

How Quantum PharmaTech Services Excels in Cleanroom Design

At Quantum PharmaTech Services, we understand the unique requirements of every industry. Our cleanroom solutions are tailored to your specific needs, ensuring optimal performance and compliance. Here’s how we make a difference:

-

Custom Solutions: From initial consultation to final implementation, we design cleanrooms that align with your processes and goals.

-

Expertise in Regulations: Our team ensures your cleanroom complies with ISO, GMP, and other regulatory requirements.

-

Innovative Technology: We use cutting-edge tools and materials for efficient and durable designs.

-

Comprehensive Support: From maintenance services to staff training, we provide end-to-end support to keep your cleanroom running flawlessly.

Trends in Cleanroom Design

-

Energy-Efficient Systems: Reducing operational costs with low-energy air handling units.

-

Modular Cleanrooms: Offering flexibility and faster installation for businesses needing scalable solutions.

-

Smart Technologies: Integration of IoT and automation for real-time monitoring of air quality, pressure, and temperature.

-

Sustainability: Focus on eco-friendly materials and energy-efficient HVAC systems.

Why Choose Quantum PharmaTech Services?

When it comes to cleanroom design, Quantum PharmaTech Services stands out as a trusted partner. Our team combines technical expertise, innovation, and a customer-centric approach to deliver cleanroom solutions that exceed expectations. Whether you’re setting up a new facility or upgrading an existing one, we’re here to help you achieve contamination-free excellence.

Final Thoughts

Cleanroom design is not just about meeting regulatory standards; it’s about creating a space that enhances productivity, ensures safety, and supports innovation. With the right partner, like Quantum PharmaTech Services, you can achieve all this and more. Contact us today to learn how we can bring your cleanroom vision to life.

What's Your Reaction?