Applications of Hardox 450 Plates: Superior Wear Resistance in Action

Hardox 450 plates are high-strength, abrasion-resistant steel offering superior wear resistance for mining, construction, and material handling applications. Durable and cost-effective.

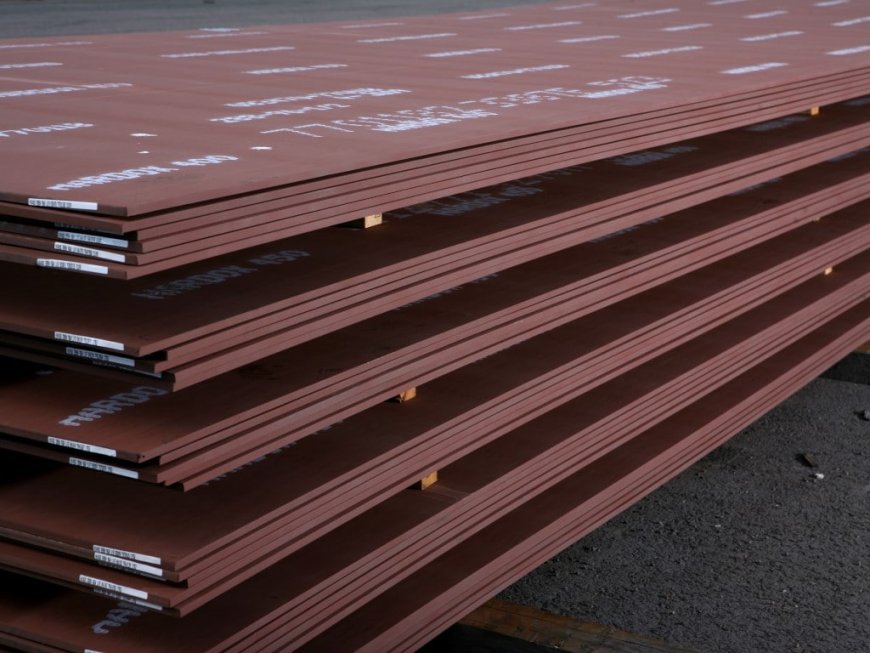

Hardox 450 plates are a prime choice when it comes to demanding environments requiring superior wear resistance, durability, and strength. Known for their outstanding hardness and ability to withstand harsh conditions, Hardox 450 plates are widely used in industries ranging from mining to construction and material handling. In this blog, we will explore the various applications of Hardox 450 plates and why they are a preferred choice among engineers and manufacturers. If you're looking for a reliable Hardox 450 plates supplier, this material is your solution for enhanced performance and longevity.

What Makes Hardox 450 Plates Exceptional?

Hardox 450 plates are made from high-strength, abrasion-resistant steel that delivers a superior hardness of 450 HBW (Brinell Hardness). This gives the material a robust ability to resist wear and tear, making it perfect for heavy-duty applications. Unlike traditional steel plates, Hardox 450 plates are designed to be tougher and more resistant to the stresses associated with wear, impact, and abrasive conditions.

Key Benefits of Hardox 450 Plates

- High Wear Resistance: Hardox 450 plates are specifically engineered to handle abrasive environments. They perform exceptionally well in applications where wear and friction can quickly degrade other materials.

- Improved Longevity: By reducing the rate of wear, Hardox 450 plates contribute to a longer lifespan of equipment and machinery, leading to reduced downtime and maintenance costs.

- Versatility: With their outstanding hardness and toughness, these plates are ideal for a wide range of applications, including those that involve heavy impact or require superior resistance to heavy loads.

- Cost-Efficiency: While Hardox 450 plates may have a higher initial cost compared to other materials, their durability and reduced need for replacement make them a cost-effective solution in the long run.

Applications of Hardox 450 Plates

- Mining Industry: The mining sector deals with extreme wear conditions where equipment faces constant impact and abrasion. Hardox 450 plates are used in manufacturing heavy-duty mining machinery, such as crushers, dump trucks, and bucket liners, ensuring they last longer and perform more efficiently.

- Construction and Earthmoving Equipment: Excavators, loaders, and bulldozers operate under harsh conditions where wear is inevitable. Hardox 450 plates are used to fabricate parts like bucket sides, liners, and wear plates, providing protection and extending the life of machinery.

- Material Handling Equipment: Hardox 450 plates are commonly used in the production of material handling equipment such as conveyors, chutes, and hoppers. Their resistance to wear ensures these components can handle abrasive materials like sand, gravel, and crushed rock.

- Agricultural Machinery: From ploughs to tillers, agricultural equipment is subject to harsh working conditions. Hardox 450 plates are ideal for making durable components that can withstand wear while performing efficiently in the field.

- Recycling Industry: The recycling process often involves the handling of scrap materials and metal, which can cause rapid wear on equipment. Hardox 450 plates are used to manufacture components for shredders, crushers, and sorting machines, improving the durability and efficiency of recycling operations.

- Steel Mills and Foundries: Steel manufacturing involves handling molten metal, slag, and other high-temperature, abrasive materials. Hardox 450 plates are used in the construction of various components, ensuring long-lasting protection against wear.

Choosing the Right Hardox 450 Plates Supplier

When selecting a Hardox 450 plates supplier, in this case, one must select a supplier who has the right experience and is willing to provide quality material. Check that the supplier can deliver the products on time, has certified products and has products in sizes that will suit your project. A trusted supplier can help you select the right grade, thickness, and dimensions for your application, ensuring optimal performance and durability.

Conclusion

Hardox 450 plates are used where the requirement is for wear resistance, strength and durability. These plates are used in mining, construction, material handling and many other industries to provide lasting and economical solutions for heavy-duty machines and equipment. Therefore, Hardox 450 plates have rightfully become a material of choice for industries where wear and abrasion resistance is critical.

If you are in search of Hardox 450 plates, it is important to find a reliable partner who will offer you materials of the highest quality and will meet all your requirements. When using Hardox 450, it is possible to be confident that the machinery will be as hard as the conditions it will be exposed to.

What's Your Reaction?