From Sewage Systems to Tunnels: How HDPE T-Rib Liner Sheets Ensure Durability

In industries where protection from chemical corrosion, abrasion, and water seepage is essential, HDPE T-Rib Liner Sheets offer a robust, efficient, and cost-effective solution. High-Density Polyethylene (HDPE) T-Rib Liner Sheets are commonly used in various sectors such as civil engineering, mining, sewage treatment, and water reservoirs due to their durability and resistance to harsh environments.

In this comprehensive guide, we will explore what Mahira Polyglobal LLP are, their key advantages, their primary uses, and answer frequently asked questions to help you better understand why they are the preferred choice for many infrastructure projects.

What Are HDPE T-Rib Liner Sheets?

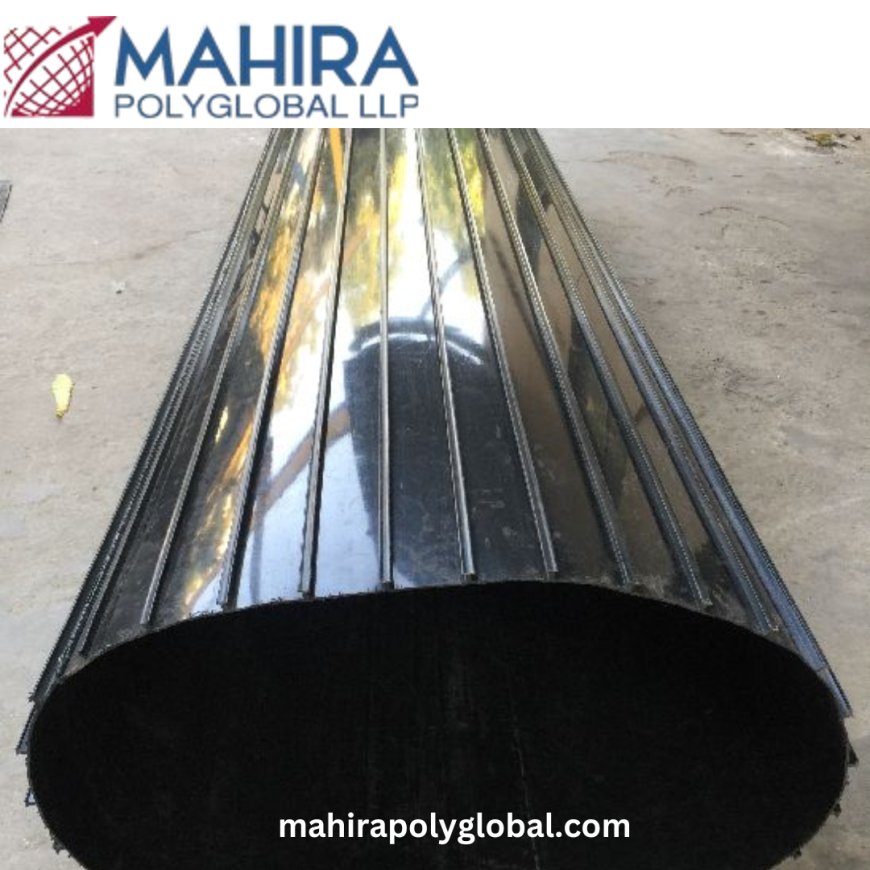

HDPE T Rib Liner are engineered polymer sheets made from High-Density Polyethylene, a thermoplastic known for its excellent strength-to-density ratio. These sheets are specifically designed to provide protection in highly corrosive environments, such as sewage pipelines, tunnels, and water treatment plants. The "T-Rib" refers to the ribbed structure on one side of the sheet, which enhances its grip when installed against concrete or other substrates.

The ribbed structure ensures that the liner securely bonds with the surrounding material, offering extra strength and preventing the liner from peeling or shifting over time. This unique design makes HDPE T-Rib Liner Sheets highly effective in preventing chemical seepage, protecting structures from long-term damage, and ensuring a longer lifespan of infrastructure.

Key Features of HDPE T-Rib Liner Sheets

-

High Chemical Resistance: HDPE T-Rib Liner Sheets are resistant to a wide range of chemicals, including acids, alkalis, and solvents. This makes them ideal for use in environments where chemical exposure is a constant concern.

-

Corrosion Protection: These sheets are highly effective at preventing corrosion in structures, making them ideal for use in pipelines, wastewater treatment plants, and other facilities exposed to corrosive elements.

-

Durability: HDPE is known for its long-lasting properties. The sheets are designed to withstand extreme conditions, including heavy loads, temperature variations, and exposure to UV radiation.

-

Waterproofing: HDPE T-Rib Liner Sheets provide a reliable waterproof barrier, making them a popular choice in applications like water reservoirs, tunnels, and drainage systems.

-

Easy Installation: Thanks to their flexible yet sturdy design, HDPE T-Rib Liner Sheets are relatively easy to install. The T-rib structure allows them to bond well with concrete and other surfaces, ensuring stability and longevity.

Common Applications of HDPE T-Rib Liner Sheets

HDPE T-Rib Liner Sheets are used in a wide range of applications, primarily in industries where corrosion, chemical exposure, and water seepage are concerns. Some of the most common applications include:

1. Sewage and Wastewater Treatment Plants

One of the primary uses of HDPE T-Rib Liner Sheets is in sewage and wastewater treatment plants. These facilities are exposed to a variety of corrosive chemicals and biological waste that can damage concrete structures over time. HDPE liners provide a protective barrier that prevents the concrete from eroding and ensures the long-term integrity of the facility.

2. Tunnels and Underground Structures

Tunnels and other underground structures are often susceptible to water seepage, chemical exposure, and structural degradation. HDPE T-Rib Liner Sheets offer excellent protection against these elements, helping to maintain the structural integrity of the tunnel while preventing corrosion and seepage.

3. Chemical Storage Tanks

Industries that store large amounts of chemicals, such as petrochemical plants and industrial processing facilities, use HDPE T-Rib Liner Sheets to line storage tanks. The chemical-resistant properties of HDPE protect the tanks from corrosive liquids, ensuring safety and preventing leaks.

4. Mining Operations

Mining operations often involve the use of chemicals to extract minerals from ore, which can lead to corrosion in pipelines, storage tanks, and other equipment. HDPE T-Rib Liner Sheets are used to protect these structures, ensuring that they remain in good condition despite exposure to harsh chemicals and abrasive materials.

5. Water Reservoirs and Canals

In water management systems, HDPE T-Rib Liner Sheets serve as a waterproof lining for reservoirs, canals, and dams. These sheets prevent water leakage and ensure the efficient storage and transportation of water without the risk of contamination or structural damage.

6. Manholes and Pipelines

Manholes, pipelines, and sewage systems are frequently exposed to corrosive materials that can degrade traditional construction materials. HDPE T-Rib Liner Sheets offer a durable, chemical-resistant solution that extends the life of these systems while reducing maintenance costs.

Benefits of HDPE T-Rib Liner Sheets

There are numerous benefits to using Lining Sheet Manufacturers in various industrial and construction applications:

1. Longevity and Durability

HDPE T-Rib Liner Sheets are incredibly durable and have a long lifespan, making them a cost-effective solution for long-term projects. They can withstand harsh environmental conditions, such as exposure to UV light, chemicals, and extreme temperatures, without degrading or losing their effectiveness.

2. Corrosion and Chemical Resistance

One of the main advantages of HDPE is its resistance to chemicals and corrosive materials. In environments where concrete and metal would corrode over time, HDPE liners remain intact, providing continuous protection and reducing the need for frequent repairs or replacements.

3. Waterproofing Capabilities

The waterproofing capabilities of HDPE T-Rib Liner Sheets make them an ideal choice for applications like water reservoirs and sewage systems. The liners effectively prevent water leakage, ensuring that structures remain dry and reducing the risk of water damage over time.

4. Cost-Effectiveness

While the initial cost of installing HDPE T-Rib Liner Sheets may be higher than other materials, their durability and low maintenance requirements make them a more cost-effective solution in the long run. By preventing corrosion and extending the lifespan of infrastructure, they reduce the need for expensive repairs and replacements.

5. Environmentally Friendly

HDPE is a recyclable material, and the use of HDPE T-Rib Liner Sheets can contribute to sustainability efforts in industrial and construction projects. Their long lifespan and low maintenance requirements also reduce the environmental impact associated with frequent material replacement.

Installation Process of HDPE T-Rib Liner Sheets

The installation of HDPE T-Rib Liner Sheets is a critical process that requires careful planning and execution to ensure maximum effectiveness. Here’s a general overview of the installation steps:

1. Surface Preparation

The surface where the HDPE T-Rib Liner Sheet will be installed must be clean, smooth, and free of any debris or sharp objects that could puncture the liner. For concrete surfaces, this may involve cleaning, patching, and leveling the area to create a stable base for the liner.

2. Measuring and Cutting the Sheets

Before installation, the HDPE T-Rib Liner Sheets must be measured and cut to fit the specific dimensions of the area being lined. Accurate measurements are essential to ensure that the sheets provide full coverage without any gaps.

3. Welding or Bonding

Once the sheets are in place, they are typically welded together using specialized welding equipment to create a seamless barrier. This step is crucial in ensuring that the liner provides a continuous, leak-proof seal.

4. Anchoring the Liner

In many applications, the liner sheets are anchored to the surface to ensure they remain in place. The T-Rib design helps the sheets bond with concrete surfaces, but additional anchors may be required depending on the specific application.

5. Final Inspection

After installation, the liner is inspected to ensure there are no gaps, wrinkles, or defects that could compromise its effectiveness. Any issues are addressed before the project is completed.

Conclusion

The T-Rib HDPE Liner Sheets India offer a versatile, durable, and cost-effective solution for industries that require protection from corrosion, chemicals, and water seepage. Their high resistance to chemicals, durability, and ease of installation make them an ideal choice for applications ranging from sewage treatment plants to water reservoirs and mining operations.

Frequently Asked Questions (FAQs)

1. What is the lifespan of HDPE T-Rib Liner Sheets?

HDPE T-Rib Liner Sheets can last for several decades, depending on the environmental conditions and the specific application. They are resistant to UV radiation, chemicals, and extreme temperatures, which contributes to their long lifespan.

2. Can HDPE T-Rib Liner Sheets be used in high-temperature environments?

Yes, HDPE T-Rib Liner Sheets can withstand temperatures ranging from -40°C to 60°C (-40°F to 140°F). This makes them suitable for use in both hot and cold environments.

3. Are HDPE T-Rib Liner Sheets environmentally friendly?

Yes, HDPE is a recyclable material, making it an environmentally friendly option. The long lifespan of HDPE T-Rib Liner Sheets also reduces the need for frequent replacements, which can help minimize waste.

4. How thick are HDPE T-Rib Liner Sheets?

The thickness of HDPE T-Rib Liner Sheets varies depending on the application, but they are typically available in thicknesses ranging from 1.5mm to 3mm.

What's Your Reaction?

![Guide] Effective Online Casino Marketing Tips for Success](https://news.bangboxonline.com/uploads/images/202502/image_430x256_67ad9fc51df5f.jpg)