In industries that require long-lasting protection against water leakage, chemical corrosion, and environmental degradation, HDPE T-Rib Liner Sheets are a game-changing solution. These liners offer unparalleled durability, ease of installation, and resistance to harsh conditions, making them the preferred choice for numerous infrastructure projects. Whether used in wastewater treatment plants, tunnels, or chemical storage tanks, HDPE T-Rib Liner Sheets are critical in safeguarding structures and extending their life spans.

This article Mahira Polyglobal LLP delves into the features, advantages, common applications, and frequently asked questions (FAQs) about HDPE T-Rib Liner Sheets, offering a comprehensive overview of this versatile and essential product.

What are HDPE T-Rib Liner Sheets?

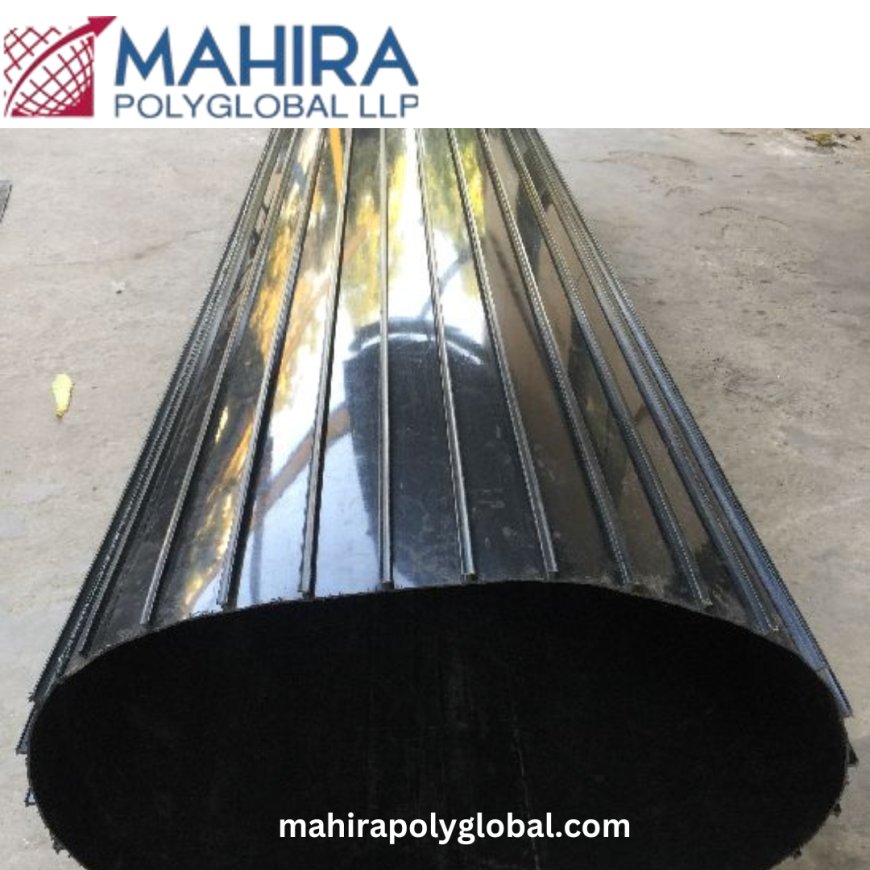

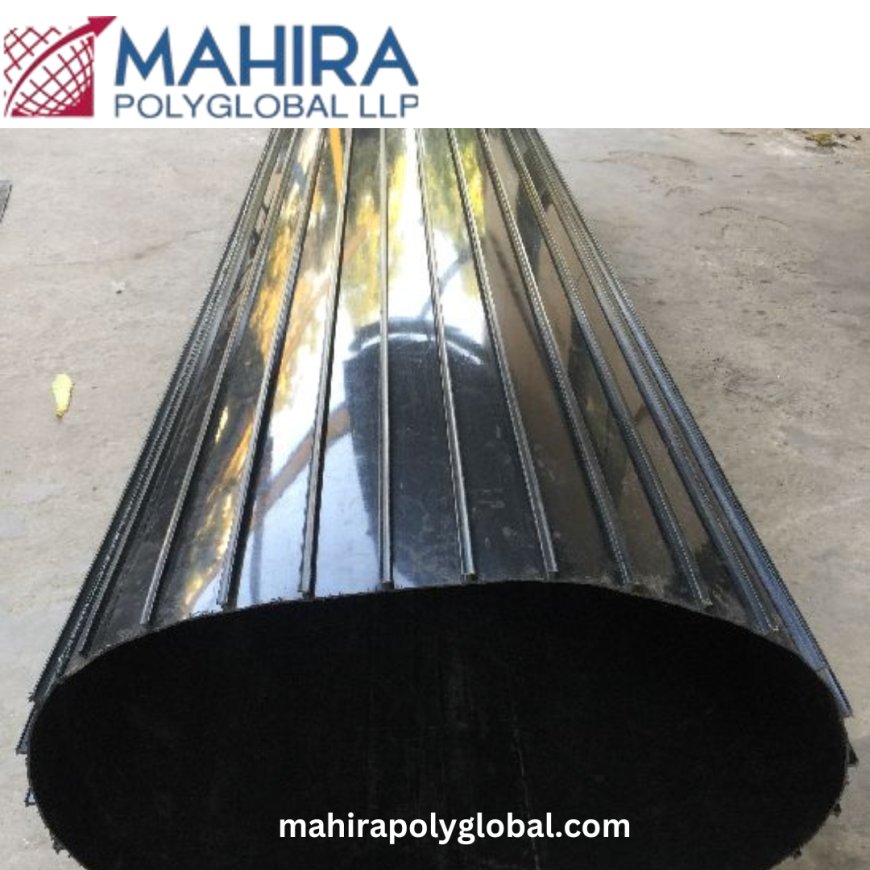

HDPE (High-Density Polyethylene) T-Rib Liner Sheets are designed with T-shaped ribs that anchor them to concrete surfaces. These liners are used to provide protection against corrosion, chemical attacks, and water infiltration in various industrial settings. The ribs increase the mechanical bond with concrete, ensuring that the liner remains securely attached, even in challenging environments.

HDPE material is known for its toughness, resistance to chemicals, and impermeability to water, making it an ideal choice for lining structures exposed to aggressive environments.

Key Features of HDPE T-Rib Liner Sheets

1. Corrosion Resistance

One of the primary features of HDPE T-Rib Liner Sheets is their excellent resistance to chemical corrosion. In environments where acidic or basic substances would damage traditional materials like steel or concrete, HDPE liners maintain their integrity. This makes them indispensable for industries such as wastewater treatment and chemical processing, where exposure to corrosive materials is routine.

2. Superior Bonding with Concrete

The T-shaped ribs in the liner allow for a strong mechanical bond with concrete. During the concrete curing process, the ribs embed themselves into the surface, creating a highly secure attachment. This prevents the liner from shifting or detaching under pressure or environmental stress, ensuring long-term durability.

3. Durability

HDPE T-Rib Liners are designed to withstand extreme conditions. They are highly durable and resistant to mechanical wear, making them suitable for heavy-duty applications such as mining and industrial storage tanks. The liners are also resistant to UV rays and temperature fluctuations, making them ideal for both outdoor and underground installations.

4. Waterproofing and Chemical Resistance

HDPE is inherently impermeable, offering exceptional waterproofing capabilities. This makes the liners ideal for use in water containment structures, including tunnels, canals, and reservoirs. Additionally, HDPE’s chemical resistance protects structures from chemical degradation, whether they are exposed to aggressive acids or alkaline solutions.

5. Low Maintenance

Once installed, HDPE T-Rib Liner Sheets require minimal maintenance. Their resistance to chemicals, moisture, and wear reduces the need for repairs, helping to lower the overall cost of ownership over the life of the structure.

6. Ease of Installation

Despite their toughness and durability, HDPE T-Rib Liners are lightweight and easy to install. They can be welded together to create a seamless barrier, ensuring complete waterproofing and protection. The installation process is quick and efficient, reducing downtime and labor costs.

Common Applications of HDPE T-Rib Liner Sheets

The Lining Sheet Manufacturers are widely used across various industries, primarily for applications requiring waterproofing, corrosion protection, and chemical resistance. Here are some of the most common use cases:

1. Wastewater Treatment Plants

Wastewater treatment plants are exposed to a wide range of chemicals and corrosive substances. HDPE T-Rib Liner Sheets protect concrete tanks, pipes, and other structures from chemical damage and water infiltration, ensuring the facility’s longevity and efficiency. The liners also help prevent leaks, which can result in costly damage or contamination.

2. Tunnels and Underground Structures

In tunnels, subways, and other underground structures, water infiltration can lead to structural weakening and eventual failure. HDPE T-Rib Liners create a waterproof barrier that prevents moisture from seeping into the concrete, protecting the structure from degradation. They are often used in transportation tunnels, sewage systems, and utility conduits to ensure long-term performance.

3. Chemical Storage Tanks

Chemical storage tanks require robust protection against corrosive liquids. HDPE T-Rib Liners provide an effective solution, preventing the tank’s concrete or metal walls from being damaged by aggressive chemicals. These liners ensure the safe storage of chemicals while minimizing the risk of leakage or contamination.

4. Mining Industry

In the mining industry, materials such as tailings and slurries can be highly corrosive and abrasive. HDPE T-Rib Liners are used in ponds, pipes, and storage tanks to protect against chemical attack and mechanical wear. The liners help to extend the life of equipment and infrastructure, reducing downtime and replacement costs.

5. Canals, Reservoirs, and Dams

HDPE T-Rib Liners are widely used in water containment systems such as canals, reservoirs, and dams. Their waterproofing capabilities prevent water loss and protect the structures from erosion. The liners are also used in irrigation systems to improve water efficiency by reducing leakage and seepage.

6. Marine and Coastal Structures

Saltwater environments are highly corrosive, making marine structures susceptible to rapid degradation. HDPE T-Rib Liners protect seawalls, docks, and jetties from saltwater corrosion, ensuring that these structures can withstand the harsh marine environment. The liners also help prevent erosion caused by wave action and tides.

Benefits of HDPE T-Rib Liner Sheets

1. Extended Service Life

By protecting concrete and other materials from chemical and water damage, HDPE T-Rib Liners significantly extend the service life of structures. This durability reduces the need for costly repairs and replacements, providing long-term savings.

2. Environmentally Friendly

HDPE is a recyclable material, and its use in lining structures prevents environmental contamination by containing chemicals and wastewater. This makes HDPE T-Rib Liners an eco-friendly solution for industrial applications, contributing to cleaner, safer environments.

3. Cost-Effective

Compared to other lining solutions like epoxy coatings or metal linings, HDPE T-Rib Liners offer a more cost-effective option. Their ease of installation, low maintenance requirements, and long service life contribute to overall cost savings.

4. High Chemical and Abrasion Resistance

HDPE T-Rib Liners are highly resistant to a wide range of chemicals, including acids, bases, salts, and hydrocarbons. They are also resistant to abrasion, making them suitable for environments where mechanical wear is a concern.

5. Seamless Installation

HDPE T-Rib Liners can be welded together to create a seamless barrier. This eliminates the potential for gaps or weak points where leaks or corrosion could occur, ensuring a high level of protection.

Conclusion

HDPE T-Rib Liner Sheets offer a versatile and cost-effective solution for protecting structures from water infiltration, chemical corrosion, and environmental wear. Their durability, ease of installation, and adaptability to a wide range of applications make them an indispensable tool for industries such as wastewater treatment, mining, and marine construction. By providing long-lasting protection and reducing maintenance needs, HDPE T-Rib Liners ensure the longevity and integrity of critical infrastructure. Whether you're building tunnels, reservoirs, or chemical storage tanks, HDPE T Rib Liner provide the reliable protection needed to withstand the harshest conditions.

Frequently Asked Questions (FAQs)

1. What is the primary function of HDPE T-Rib Liner Sheets?

HDPE T-Rib Liner Sheets are primarily used for waterproofing and protecting structures from chemical corrosion. They are designed to bond with concrete, providing a durable barrier against water infiltration and aggressive chemicals.

2. Where are HDPE T-Rib Liner Sheets commonly used?

These liners are commonly used in wastewater treatment plants, chemical storage tanks, mining operations, tunnels, canals, reservoirs, and marine structures. They offer protection against water, chemicals, and abrasion in these demanding environments.

3. How are HDPE T-Rib Liner Sheets installed?

HDPE T-Rib Liners are typically installed by heat welding the sheets together, creating a seamless and leak-proof barrier. The T-shaped ribs embed into the concrete, providing a secure mechanical bond. Installation is relatively quick and easy, requiring minimal tools and labor.

4. How long do HDPE T-Rib Liner Sheets last?

With proper installation and maintenance, HDPE T-Rib Liner Sheets can last for decades. Their chemical resistance, durability, and UV stability allow them to withstand harsh environmental conditions for long periods without degrading.