How Do Rotary Vane Vacuum Pumps and Liquid Ring Pumps Handle Vapor and Gas Compression?

When it entails coping with vapor and fuel compression in industrial packages, rotary vane vacuum pumps and liquid ring vacuum pumps are broadly used technologies.

When it entails coping with vapor and fuel compression in industrial packages, rotary vane vacuum pumps and liquid ring vacuum pumps are broadly used technologies. Each operates with precise mechanisms, supplying distinct benefits counting on the software. But how do they efficiently handle the complex tactics of vapor and gasoline compression? This weblog explores their functionality, average overall performance, and suitability for diverse industries.

Understanding Rotary Vane Vacuum Pumps

A rotary vane vacuum pump is a mechanical device that uses a simple yet exceptionally inexperienced design to create a vacuum and compress gases. At its center, it includes a rotor mounted interior a cylindrical housing. The rotor competencies vanes that slide outward due to centrifugal pressure, developing sealed cubicles within the chamber. As the rotor spins, the ones cubicles compress and switch fuel through the device.

When it comes to vapor compression, rotary vane vacuum pumps excel due to their functionality to cope with non-stop and easy gas go along with the waft. The system starts offevolved while vapor or fuel enters via the inlet port. The rotating vanes lure the gasoline within the compression chamber, reducing the amount and growing strain as the rotor spins. Once the compression section is whole, the gas is expelled via the exhaust port. This seamless operation ensures green vapor compression, making rotary vane pumps appropriate for programs like vacuum packaging, medical system, and commercial enterprise production.

What Makes Liquid Ring Vacuum Pumps Different?

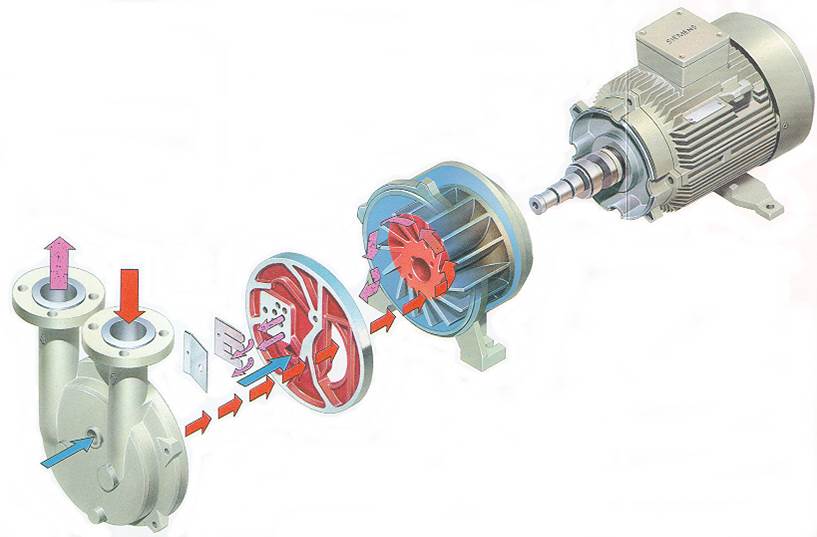

Unlike rotary vane pumps, liquid ring vacuum pumps use a liquid (usually water or oil) because the sealing medium. The pump includes an impeller set up eccentrically inner a cylindrical casing. When the impeller rotates, the liquid paperwork a hoop along the internal wall of the casing, developing chambers a few of the impeller blades. These chambers amplify and agreement during rotation, drawing in and compressing gasoline or vapor.

The unique characteristic of liquid ring vacuum pumps is their capacity to cope with wet gases or vapors correctly. During vapor compression, the liquid ring absorbs heat and manages condensation, preventing damage to the pump. This makes them especially suitable for programs wherein moisture or saturated gases are present, along with chemical processing, wastewater remedy, and electricity plants. Their capability to address corrosive and excessive-temperature gases is another key gain.

How Do Rotary Vane and Liquid Ring Pumps Compare in Handling Vapor?

Both rotary vane vacuum pumps and liquid ring vacuum pumps are inexperienced in vapor compression, but their processes differ extensively. Rotary vane pumps rely on unique mechanical motion and are ideal for programs requiring a smooth, dry vacuum. They provide fantastic performance in conditions in which the vapor is free of moisture and contaminants.

On the alternative hand, liquid ring vacuum pumps excel in hard environments in which vapors encompass moisture or corrosive elements. The liquid seal acts as a shielding barrier, ensuring that the pump operates successfully with out damage. However, liquid ring pumps can also require extra protection due to the want to fill up and manipulate the sealing liquid.

What Are the Key Advantages of Rotary Vane Vacuum Pumps?

Rotary vane vacuum pumps offer numerous advantages with reference to handling vapor and fuel compression. First, they're in particular green in developing a strong vacuum, making them excellent for precision programs. Their compact layout and coffee noise levels moreover make them appropriate for laboratory and medical use. Additionally, rotary vane pumps are seemed for their lengthy provider existence and occasional operating fees, furnished they're utilized in environments loose from excessive moisture or corrosive materials.

Why Are Liquid Ring Vacuum Pumps Preferred for Wet Applications?

Liquid ring vacuum pumps are the move-to choice for applications related to moist or saturated gases due to their potential to deal with moisture and condensation efficiently. The liquid ring no longer only seals the pump but additionally absorbs heat within the route of compression, reducing the hazard of overheating. This function makes them exceptional for industries along with food processing, wherein steam and moisture are normally encountered. Furthermore, their capability to cope with corrosive gases makes them a dependable desire for chemical and petrochemical applications.

Which Pump Is Better for Your Application?

Choosing among rotary vane vacuum pumps and liquid ring vacuum pumps relies upon in big element on the specific requirements of your utility. If your method needs a smooth, dry vacuum with minimal protection, a rotary vane pump is likely the higher alternative. Its efficiency and simplicity make it an notable preference for environments in which moisture isn't a situation.

However, in case your software program consists of wet or corrosive vapors, a liquid ring vacuum pump is extra appropriate. Its capability to manage condensation and deal with harsh gases guarantees reliable normal performance in tough environments. Additionally, liquid ring pumps are frequently desired in industries requiring a higher diploma of sturdiness and resistance to place on and tear.

How to Maximize the Performance of Vacuum Pumps?

To get the maximum out of your vacuum pump, everyday renovation and proper operation are important. For rotary vane vacuum pumps, it is vital to display screen the condition of the vanes and make sure that the pump oil is smooth and changed as needed. Proper lubrication minimizes wear and facilitates hold average performance over time.

For liquid ring vacuum pumps, preserving the liquid seal is vital. This includes regularly replenishing the sealing liquid and monitoring its exceptional to save you contamination. Additionally, periodic inspection of the impeller and casing ensures smooth operation and stops capacity failures.

Final Thoughts

Both rotary vane vacuum pumps and liquid ring vacuum pumps are extraordinarily powerful technology for handling vapor and gas compression, each with particular strengths and talents. While rotary vane pumps are perfect for dry packages requiring precision and efficiency, liquid ring pumps shine in moist and hard environments. Understanding the versions and comparing your precise needs will let you make an informed preference, ensuring best overall performance and reliability for your operations.

What's Your Reaction?