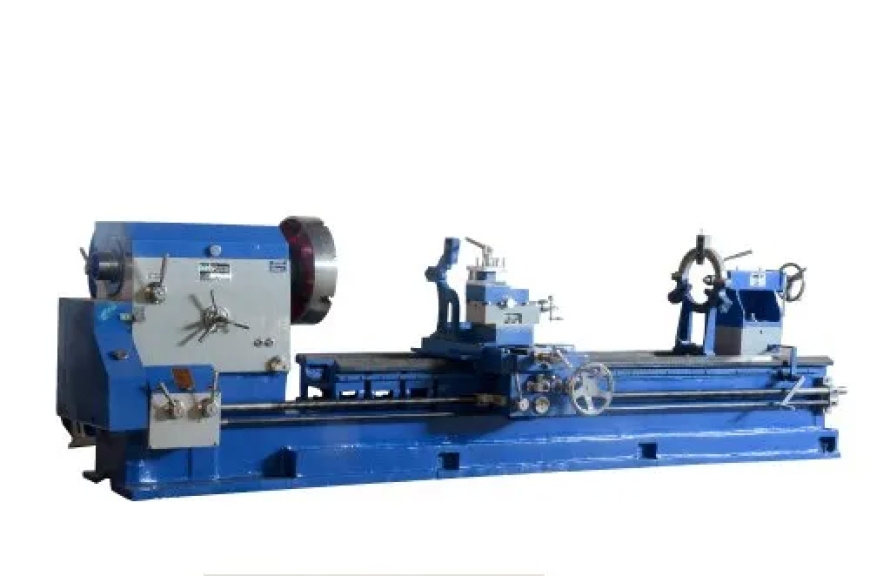

How to Use an Extra Heavy Duty Lathe Machine Safely and Effectively

Ensure your safety and maximize efficiency with an extra heavy duty lathe machine by following these step by step tips and tricks.

As a leading manufacturer of industrial machinery, we at Leader Machine Tools understand the importance of operating heavy duty equipment safely and efficiently. The extra heavy-duty lathe machine is a powerful tool that can be used for a wide range of metalworking tasks, from turning and facing to threading and knurling. However, its sheer power and size can also pose some risks if not used properly. In this blog post, we'll guide you through the key steps to using an extra heavy-duty lathe machine safely and effectively.

What is an Extra Heavy Duty Lathe Machine?

An extra heavy duty lathe machine is a type of metalworking machine that is designed to handle larger and more complex workpieces than a standard lathe. These machines are typically found in industrial workshops, manufacturing facilities, and machine shops where high-precision, heavy-duty machining is required. They are characterized by their robust construction, powerful motors, and the ability to handle workpieces of significant size and weight.

Safety Considerations for Using an Extra Heavy Duty Lathe Machine

Operating an extra heavy duty lathe machine requires a high level of safety awareness and proper training. Here are some key safety points:

- Wear appropriate Personal Protective Equipment (PPE): This includes safety glasses, gloves, steel-toed boots, and a secure, close-fitting work apron.

- Ensure proper machine setup and maintenance: Regularly inspect the machine for any signs of wear or damage, and follow the manufacturer's recommended maintenance schedule.

- Secure the workpiece: Ensure that the workpiece is securely clamped and centered on the lathe to prevent it from becoming dislodged during operation.

- Avoid loose clothing and jewelry: These can easily get caught in the rotating parts of the machine, posing a serious safety hazard.

- Keep the work area clean and organized: A cluttered workspace can increase the risk of accidents and make it more difficult to work safely.

Effective Techniques for Using an Extra Heavy Duty Lathe Machine

To use an extra heavy-duty lathe machine effectively, follow these best practices:

- Understand the machine's capabilities: Familiarize yourself with the machine's maximum speed, torque, and weight capacity to ensure that you are working within its limits.

- Start with a trial run: Before performing any critical machining operations, run a test cut on a scrap piece of material to ensure that the machine settings and tooling are appropriate for the job.

- Adjust the cutting speed and feed rate: Experiment with different cutting speeds and feed rates to find the optimal balance between productivity and surface finish.

- Monitor the workpiece and machine closely: Keep a close eye on the workpiece and the machine's operation during the machining process, and be prepared to make adjustments or stop the machine if any issues arise.

- Use the right tooling: Ensure that you are using the appropriate cutting tools, work holding devices, and accessories for the specific job at hand.

Maintenance and Troubleshooting Tips

Proper maintenance is essential for keeping an extra heavy-duty lathe machine running smoothly and safely. Here are some tips:

- Clean and lubricate the machine regularly: Follow the manufacturer's recommendations for cleaning and lubricating the machine's various components, such as the ways, spindle, and gearbox.

- Check for wear and replace parts as needed: Regularly inspect the machine for any signs of wear or damage, and replace parts as necessary to maintain optimal performance.

- Troubleshoot issues promptly: If you encounter any problems or issues with the machine, address them immediately to prevent further damage or safety concerns.

Frequently Asked Questions

Q1: What is the maximum workpiece size that an extra heavy-duty lathe machine can handle?

Ans. The maximum workpiece size that an extra conventional lathe machine can handle depends on the specific model and its technical specifications. Generally, these machines are capable of handling larger and heavier workpieces compared to standard lathes, with some models able to accommodate workpieces weighing several tons.

Q2: How do I ensure proper workpiece clamping and centering?

Ans. Proper workpiece clamping and centering is crucial for the safe and effective operation of an extra heavy-duty lathe machine. Secure the workpiece using a chuck, faceplate, or other appropriate work holding device, and ensure that it is centered and balanced on the lathe's spindle. Refer to the manufacturer's instructions for specific clamping and centering procedures.

Q3: What are the common safety hazards associated with using an extra heavy-duty lathe machine?

Ans. Some of the common safety hazards associated with using an extra heavy-duty lathe machine include the risk of being struck by a rotating workpiece, entanglement with moving parts, exposure to high-speed cutting tools, and the potential for the workpiece to become dislodged and propelled outwards. Proper safety training, the use of appropriate PPE, and following established safety protocols are essential to mitigate these risks.

Conclusion:

Using an extra heavy-duty lathe machine requires a combination of technical knowledge, practical skills, and a strong commitment to safety. By following the guidelines and best practices outlined in this blog post, you can operate these powerful machines safely and effectively, unlocking their full potential for your metalworking needs. Remember, safety should always be the top priority when working with any industrial machinery.

If you have any further questions or would like to learn more about our extra heavy-duty lathe machines, please don't hesitate to contact Leader Machine Tools, is lathe machine manufacturers in India. We're here to help you achieve your manufacturing and metalworking goals.

What's Your Reaction?