Implementing Mesh Bed Leveling for Perfect First Layers

In this article, we will discuss the advantages of mesh bed leveling. And how the procedure can be done efficiently and with ease.

It may look simple, but it can be the most challenging part of any kind of print on the 3D printer. Mesh bed leveling is one of the Print bed preparation methods. It aims at increasing the precision of the accuracy of the 1st layer. In this article, we will discuss the advantages of mesh bed leveling. And how the procedure can be done efficiently and with ease.

The Importance of a Perfect First Layer

In essence, the first layer of a 3D print is the base that sets the structure of the object on formation. The undercoating may not stick or stick unevenly to the first layer. This results in print failures, warping, and poor finishing. Since the mesh bed has individual spring-like elements, it helps in maintaining the correct distance of the nozzle above the bed. In this way, it provides a uniform layer of adhesion across the build plate.

Understanding Mesh Bed Leveling

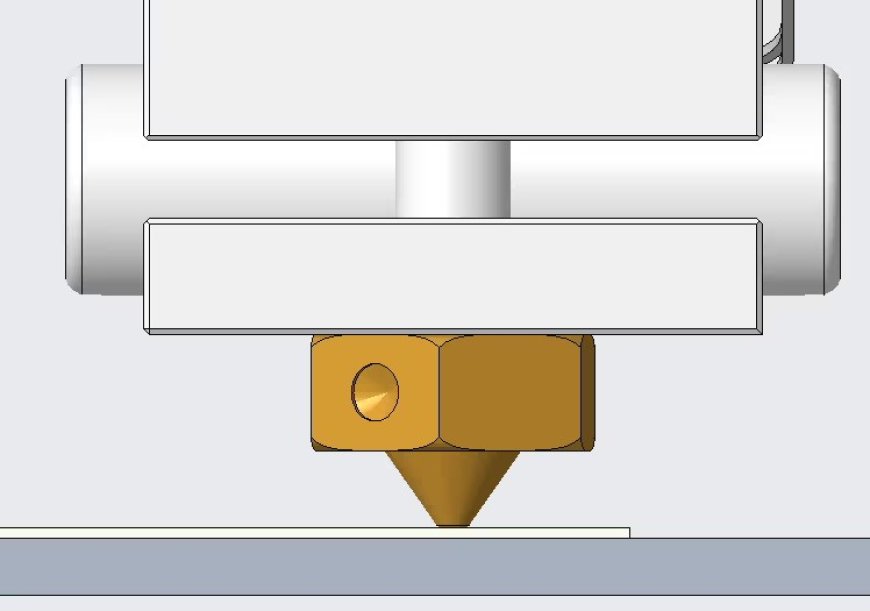

Mesh bed leveling means predicting the bed level to nearly pinpoint accuracy on the home subnet. The printer continually measures a height at many different locations on the bed and saves it. In the process of printing, the firmware controls the Z-axis. By lowering or raising it if necessary, to maintain an even surface on the bed. It therefore assists in ensuring that the nozzle remains at a constant height with the bed. Regardless of the flatness or lack of it of the bed.

Steps to Implement Mesh Bed Leveling

Here is how one can follow the mesh bed level procedure:

1. Prepare the Printer

First of all, make sure that the firmware of your printer supports the mesh bed leveling option. Check it before trying the mesh bed leveling. Most of the current generation of 3D printers have the mesh bed level function already installed in them. If necessary, you need to do a firmware update to the most current version.

2. Clean the Print Bed

After that, the z-axis should be cleaned to be put on the printer bed while maintaining accurate measurements. Wipe the bed to remove any of the filament, dust, or oils that may still be present. It can be done using isopropyl alcohol or another appropriate cleaning agent. This step minimizes the fact that the measurements may be affected by either the ground or some other surface. Instead of the actual bed.

3. Start the Leveling Process

Start the mesh bed leveling procedure using your printer console or software that is compatible with the equipment. The printer will use several points on the bed to measure distance, it shall measure width between the nozzle and the bed. It is recommended that you complete the process as described on the screen. Whether or not you make an application, contact, or deposit.

4. Adjust the Nozzle Height

Leveling the nozzle after the mesh bed leveling process has been accomplished shall come to an end. This can often be achieved via the buttons of the printer’s operational interface. Proper nozzle height is essential for a great first layer. And there is nothing worse than having a layer of goop or a gap on the first layer.

Maintaining Consistent Temperature

Another factor critical for mesh bed leveling is the ability to regulate the temperature whilst printing. Temperature variations often affect the success of the process. In this regard, the 3D Printer Prusa Silicone Sock can be a rather useful addition to a modeler’s toolkit. It is a sleeve that is fitted over the hot end thus providing an insulating layer. And keeping the temperature constant. This helps to regulate the movement and distribution of the filament. And also helps to ensure that the filament does stick to the hot end. Which aids in the production of a better first layer of the print.

Conclusion

Mesh bed, or bed leveling, is one of the many ways of ensuring that the first layers are well done in 3D printing. This helps to set the correct distance from the bed and thereby increases adhesion to the bed. Also, print quality where the bed irregularities may cause misalignment of the nozzle. It is essential to balance and control the temperature in the printing region. So, it is also advisable to implement systems such as the Prusa Silicone Sock to improve the print quality. With those rules and Mesh bed leveling, you have the chance to enhance greatly your build success rate. And the quality of your 3D building.

What's Your Reaction?