Multiple Effect Evaporator System: Efficiency and Leading Manufacturers in India

Multiple Effect Evaporator

Introduction to Multiple Effect Evaporator Systems

Multiple Effect Evaporator (MEE) systems are crucial for efficient water evaporation and concentration processes across various industries. These systems optimize energy usage by utilizing vapor from one effect to heat the next, significantly improving steam economy and reducing energy consumption. This article explores the mechanics, benefits, and top manufacturers of MEE systems in India.

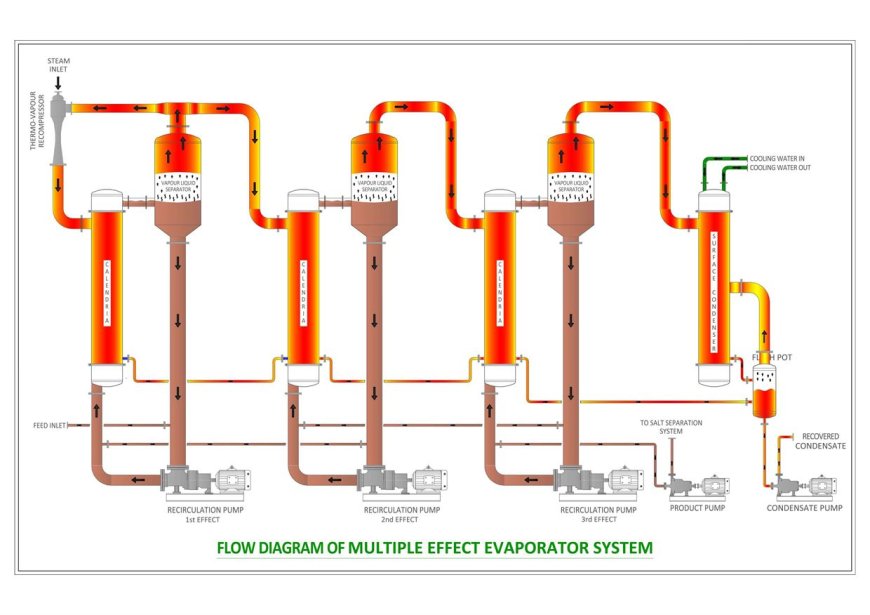

How Multiple Effect Evaporator Systems Work

In a Multiple Effect Evaporator System, steam or hot oil is introduced into the shell side of the heat exchanger in the first effect (stage). The vapor generated in the first effect is then used as the heating medium for the second effect. This process continues, with the vapor from each stage serving as the heating medium for the next. This cascading use of vapor ensures optimal energy utilization, leading to substantial steam economy.

Theory and Practical Steam Economy

The theoretical basis for MEE systems is that to evaporate 1 kg of water, 1 to 1.2 kg of steam is required. However, in practice, a Multiple Effect Evaporator system can evaporate more than 1 kg of water per 1 kg of steam used, depending on the number of effects. For instance, in a three-effect evaporator, 1 kg of steam can evaporate approximately 3 kg of water. This enhanced steam economy is a significant advantage, especially in industries where energy costs are a concern.

Vapor Recompression in MEE Systems

Vapor recompression is an advanced technique employed to further enhance the efficiency of MEE systems. The vapor recompressed from a subsequent effect can be used for heating the same effect, thus recycling the energy within the system. This method, often referred to as Thermal Vapor Recompression (TVR), helps achieve even greater steam economy and energy efficiency.

Applications of Multiple Effect Evaporator Systems

MEE systems are widely used in industries such as:

- Chemical processing

- Pharmaceuticals

- Food and beverage

- Pulp and paper

- Wastewater treatment

Their ability to efficiently concentrate solutions and handle large volumes of liquid makes them indispensable in these sectors.

Leading Multiple Effect Evaporator Manufacturers in India

India is home to several reputable manufacturers of Multiple Effect Evaporator systems, known for their innovative designs and high-quality products. Here are some leading companies:

1. Thermax Limited

Thermax Limited is a prominent player in the field of energy and environment solutions. Their Multiple Effect Evaporator systems are designed for optimal energy efficiency and are widely used in various industrial applications.

2. Praj Industries

Praj Industries is renowned for its expertise in process engineering and manufacturing. Their MEE systems are robust, efficient, and tailored to meet the specific needs of industries such as bioenergy, water treatment, and chemicals.

3. Chemdist Process Solutions

Chemdist Process Solutions specializes in designing and manufacturing MEE systems for the chemical, pharmaceutical, and food processing industries. Their systems are known for their reliability and efficiency.

4. Swenson Technology

Swenson Technology offers state-of-the-art MEE systems with a focus on energy efficiency and sustainability. Their systems are used in a wide range of industrial applications, providing high performance and reliability.

5. Aqua Process Technologies

Aqua Process Technologies is a leading manufacturer of water treatment and evaporation systems. Their MEE systems are designed to handle complex industrial processes, ensuring high efficiency and cost-effectiveness.

6. SSP Pvt. Ltd.

SSP Pvt. Ltd. is a well-known manufacturer of evaporation and drying systems. Their Multiple Effect Evaporator systems are designed for a variety of industrial applications, providing high efficiency and reliability.

7. Ravi International

Ravi International offers a wide range of MEE systems catering to different industries. Their systems are designed for optimal performance and energy efficiency, making them a preferred choice for many businesses.

8. Technoforce Solutions

Technoforce Solutions specializes in process intensification and offers advanced MEE systems. Their systems are known for their innovative designs and high energy efficiency, catering to the needs of various industries.

9. KETAV Consultant

KETAV Consultant is a leading provider of process engineering solutions, including MEE systems. Their evaporators are designed for high efficiency and are widely used in the chemical, pharmaceutical, and food processing industries.

10. EIL - Engineers India Limited

EIL provides comprehensive engineering solutions, including the design and manufacture of Multiple Effect Evaporator systems. Their systems are known for their robustness and efficiency, suitable for a wide range of industrial applications.

11. GEA Process Engineering India Pvt. Ltd.

GEA Process Engineering is a global leader with a strong presence in India, offering advanced MEE systems. Their systems are designed for high efficiency and reliability, catering to industries such as food and beverage, pharmaceuticals, and chemicals.

12. Alfa Laval India Pvt. Ltd.

Alfa Laval India provides a variety of process solutions, including MEE systems. Known for their innovative technology and energy-efficient designs, Alfa Laval’s systems are widely used in the food processing, pharmaceutical, and chemical industries.

13. Shachi Engineering Pvt. Ltd.

Shachi Engineering specializes in evaporation and drying solutions, offering MEE systems tailored to meet the specific needs of different industries. Their systems are designed for high efficiency and durability.

14. Technofab Engineers

Technofab Engineers is known for their expertise in designing and manufacturing high-quality MEE systems. Their solutions are used across various industries, including chemical processing and wastewater treatment.

MEE Manufacturers: Key Considerations

When selecting a Multiple Effect Evaporator system, several factors need to be considered:

-

Number of Effects: The optimal number of effects should be determined to balance steam economy and capital cost. More effects generally mean better steam economy but higher initial investment.

-

Material of Construction: The choice of materials for the evaporator system must be compatible with the process fluids to ensure durability and longevity.

-

Energy Efficiency: Advanced features like vapor recompression can significantly enhance energy efficiency and reduce operational costs.

-

Customization: The system should be customizable to meet the specific requirements of the industry and process it will be used for.

-

After-Sales Support: Reliable after-sales support and maintenance services are crucial for the smooth operation of the MEE system.

Conclusion

Multiple Effect Evaporator systems are vital for industries that require efficient water evaporation and concentration processes. Their ability to provide high steam economy and energy efficiency makes them a preferred choice in various sectors. In India, several manufacturers are at the forefront of providing cutting-edge MEE systems, contributing to the industrial growth and sustainability of the nation. When choosing an MEE system, it is essential to consider the number of effects, material of construction, energy efficiency, customization options, and after-sales support to ensure the best performance and value.

What's Your Reaction?

![Noots Focus Reviews [Truth Exposed 2025]!](https://news.bangboxonline.com/uploads/images/202501/image_430x256_678e3b94881a1.jpg)

![Vivalis Male Enhancement: The Must-Know Ingredients [2025 Update]](https://news.bangboxonline.com/uploads/images/202501/image_430x256_678e3b54e396c.jpg)