Optimizing CNC Precision Machining for Complex Geometries and Designs

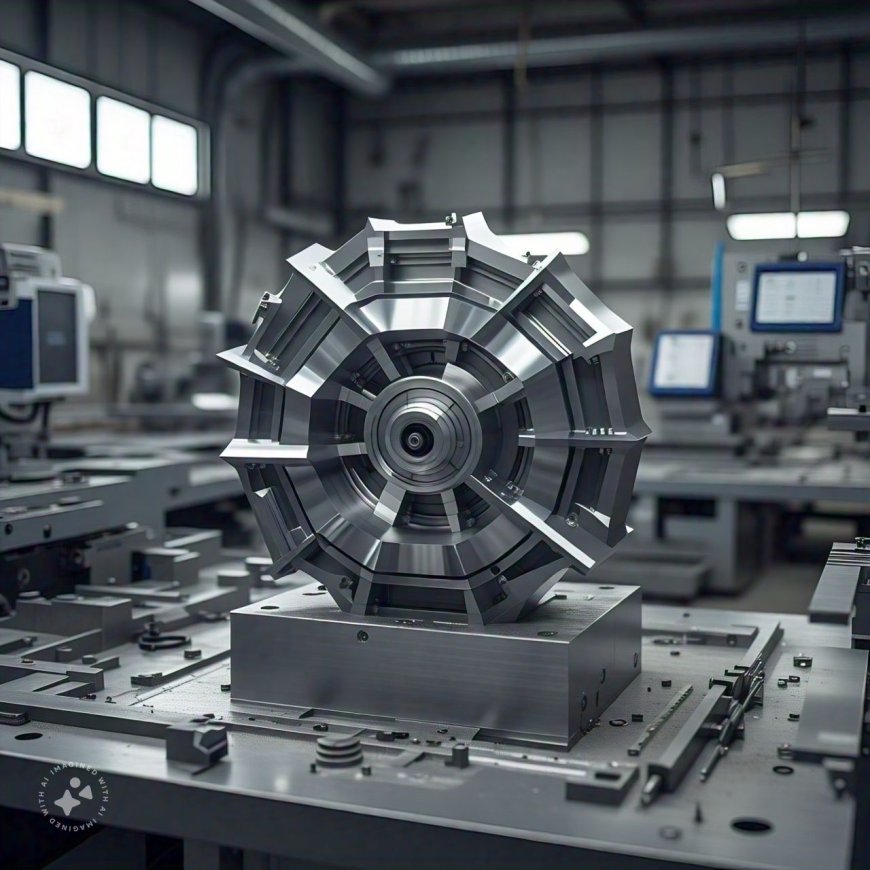

CNC precision machining has revolutionized the outlook of manufacturing which is often associated with complicated geometries and intricate designs.

CNC precision machining has revolutionized the outlook of manufacturing which is often associated with complicated geometries and intricate designs. Industry-specific requirements, whenever precise and stringent are met by CNC precision machining which brings much-needed accuracy and efficiency to the manufacturing of custom-machined parts. In the midst of thriving industries in the Middle Eastern regions, CNC precision machining aids in procuring special, high-quality components for multitude uses.

Knowing CNC Precision Machining for Complex Geometries

CNC precision machining employs state-of-the-art software for controlling high-speed tools to fabricate parts with even the most intricate shapes. Through the use of CAD models, the manufacturer is ensured that parts will meet specific specifications for aerospace, automotive, and medical equipment sectors, among others. This is quite essential for custom precision manufacturing in the Middle East, because its demand for specialized parts is accelerating, and the ability of CNC precision manufacturing to replicate complex designs well will make all the difference.

The versatility to create complex geometries with CNC machining allows it to be tolerant of intricate shapes that would otherwise be unachievable with conventional machining technologies. It is therefore a great asset for the precision custom machining manufacturer to face tough designs without compromising their accuracy. With multi-axis machining, CNC systems cut, grind, and shape the materials in specific configurations to achieve tolerances and a high-quality finish required in medical devices and even telecommunication sectors.

Advantages of Custom Precision Machining for Complex Parts

This advantage of CNC precision manufacturing is the production of identical parts, no matter how complex, with the consistency that each one has the same specifications. The services of Precision Machining and Fabrication Services in UAE rely on CNC for accuracy in product support through zero-tolerance requirements. Because of CNC machining, custom machined parts end up having the same specifications in every batch, which reduces the risk of defects.

Efficient Production Times:

CNC precision machining provides faster and more efficient customized machining parts. Through the software programs, CNC machines may operate continuously with minimal downtime, improving productivity for machining companies in UAE and across the world. Such efficiency works to cut down on production costs with increased time to market, which is an essential factor for some industries with little wiggle room for deadlines.

Adaptability for Complex Geometries:

Traditional manufacturing techniques usually cannot handle complex shapes or angles. Rather, CNC machines can easily adapt to create complex patterns and designs with extreme details. This ability is essential in precision custom machining manufacturers projects, where each part may have unique configurations. For instance, in high-tech industries that require custom precision machining, CNC machines can carry out difficult cuts that otherwise would not be possible.

Material Versatility:

CNC machines are highly versatile and can be utilized in machining and fabrication of wide-ranging materials-from metals to plastics and even composites. This versatility becomes very useful for precision machining and fabrication services in the UAE, wherein manufacturers could demand CNC machines in order to fabricate parts in a variety of materials as the project demands. Industries can choose the best material without having to sacrifice the design complexity in this kind of precision manufacturing via CNC.

Key Applications of CNC Precision Machining in the Middle East

There is a growing demand for precision machining in the Middle East, especially in areas that require specialized parts produced through advanced manufacturing techniques. As such, precision manufacturing companies in the region are investing in state-of-the-art CNC technologies that are assisting them in meeting the demands of the markets involved.

Aerospace and Defence:

Several of the products in the aerospace industry are custom machined to have intricate designs that require very high precision, thus, very small tolerance. Custom precision manufacturing in the Middle East is very beneficial to aerospace companies looking for reliable suppliers of their complex components. Most industries utilizing cnc machine parts manufacturers can only produce highly reliable light weight parts that would withstand extreme conditions.

Oil and Gas Industry :

The oil and gas industry requires parts to be strong and accurate, like valves, fittings, and pumps. This can be achieved through CNC machining. With harsh environmental conditions and strict specifications, custom machined parts manufactured by precision machining companies in the UAE ensure the long life and efficiency of equipment in this industry.

Medical Equipment:

There are a few specialized tools and pieces of equipment in the medical business that must have stringent quality requirements and would be manufactured using CNC precision machining. The manufacturers of precision custom machining will be required to meet quite stringent standards regarding accuracy, cleanliness, and compatibility with particular materials. Medical parts need to meet these standards through CNC machining and, thus, have the latitude for use in mission-critical situations.

Automotive Manufacturing:

Precision machining in the Middle East has also grown with the automotive industry, which is highly specialized to deliver high-quality components, precision engineered. CNC precision machining plays a significant role in engine parts, brackets, and any other custom machined auto parts. The procedure not only gives more functionality to the auto parts but also ensures consistency across huge volumes.

CNC Precision Machining Techniques for Higher Precision

Here are some of the techniques used by manufacturers to optimize CNC precision machining for complex geometries:

Multi-Axis Machining:

Modern CNC machines are designed to work in different axes. There is now 3-axis, 4-axis, and 5-axis machining that can create complex geometries with fewer setups. This is important for complex parts requirements in defense and aerospace industries.

Computer-Aided Manufacturing (CAM):

CAM software enables precision customizing manufacturers to create and code the machining process with precise accuracy. CAM is the crucial role that guarantees that all cuts carried out by CNC machines are followed to the letter with no errors at all.

High-Speed Machining:

High-speed machining significantly increases the production rate and results in a good quality surface finish. Its use of high-speed spindles and optimized tool paths help the Leading Manufacturing Solutions reduce cycle times without compromising the precision, which works as perfect for precision manufacturing companies for meeting tight deadlines without giving away on quality.

Choosing a Precision Manufacturing Company

Along the most important factors to be considered in choosing a reliable precision manufacturing company is if it has an experience concerning CNC precision manufacturing, already has multi-axis machines for complex designs, and has a track record of producing quality parts. A good CNC machine parts manufacturer who could work on complex designs and even on complex materials will have good results in a project and minimize possible defects in production.

Conclusion

Advanced technologies, experienced technicians, and good quality control can help with the machining of complex geometries and designs for CNC Precision Machining. Due to its relative flexibility and precision, the process is an absolute necessity for custom precision manufacturing in the Middle East. Medical, aerospace, automotive, and industrial are among the sectors where CNC precision manufacturing plays a significant role in supporting industries that rely on precise, high-quality custom machined parts.

What's Your Reaction?