The Basics of CIPP Liners What You Need to Know

In the world of modern plumbing and infrastructure maintenance, CIPP liners represent a significant advancement in technology. CIPP, or Cured-In-Place Pipe, is a trenchless pipe rehabilitation method that has gained prominence for its effectiveness and efficiency. Understanding the basics of CIPP liners is essential for anyone involved in plumbing, sewer repairs, or infrastructure management. This comprehensive guide will cover the fundamentals of CIPP liners, their benefits, applications, and installation process, providing you with a clear understanding of this innovative solution.

What is a CIPP Liner?

A CIPP liner is a type of flexible, resin-saturated liner used to rehabilitate and repair existing pipes without the need for extensive excavation. The process involves inserting the liner into the damaged pipe, curing it to form a new, solid pipe within the old one. The result is a seamless, durable, and corrosion-resistant pipe that restores the functionality of the original system.

The CIPP method is known for its minimal disruption to the surrounding environment. Traditional pipe repair methods often require digging up large sections of ground, causing significant disturbance to landscapes, roads, and other infrastructure. In contrast, CIPP liner installation is a trenchless technology, meaning it requires only small access points to complete the repair, making it a more efficient and less invasive option.

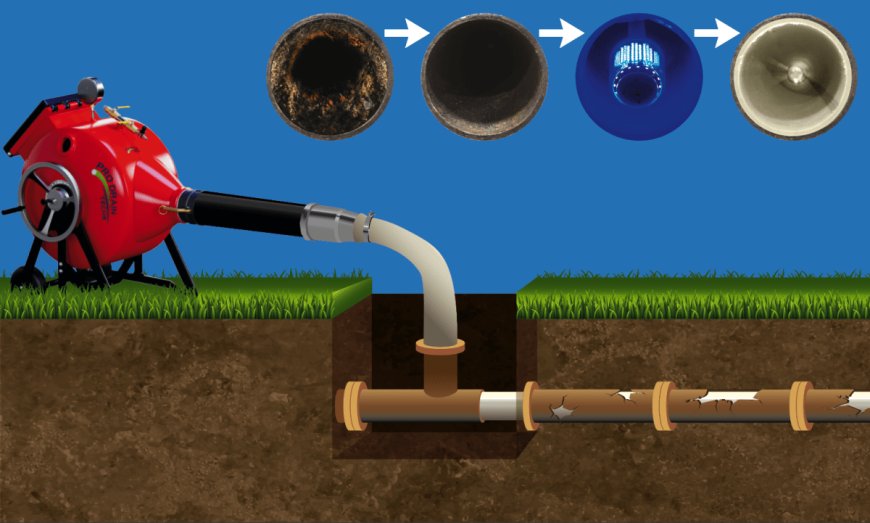

How CIPP Liners Work

The process of using a CIPP liner involves several key steps:

-

Inspection and Assessment: Before installation, a thorough inspection of the existing pipe is conducted. This is typically done using closed-circuit television (CCTV) cameras, which provide a detailed view of the pipe's condition. The inspection helps identify the extent of the damage, such as cracks, corrosion, or blockages, and determines the best approach for installation.

-

Pipe Cleaning: Once the inspection is complete, the pipe is cleaned to remove debris, scale, or other obstructions. This step is crucial for ensuring proper adhesion of the CIPP liner. Cleaning is usually performed using high-pressure water jets or mechanical tools designed to clear the interior of the pipe.

-

Liner Preparation: The CIPP liner is prepared by saturating it with a resin. The resin can be made from various materials, such as epoxy, polyester, or vinyl ester. The choice of resin depends on factors such as the type of pipe being repaired and the environmental conditions.

-

Liner Insertion: After preparation, the CIPP liner is inserted into the existing pipe. This is done using a winch or other mechanical means to pull the liner through the pipe until it reaches the desired location.

-

Liner Inflation: Once in place, the liner is inflated using air or water pressure. This causes the liner to conform to the shape of the existing pipe, ensuring a tight fit and complete coverage of any damage.

-

Curing: The resin-saturated liner is then cured to harden and form a new pipe within the old one. Curing can be achieved using various methods, including heat, steam, or ultraviolet (UV) light. The curing process solidifies the resin, creating a durable and seamless pipe lining.

-

Final Inspection and Testing: After curing, a final inspection is conducted to ensure that the new pipe lining is properly installed and functioning as expected. This may involve running water through the system and checking for any leaks or issues.

-

Restoration: If any access points or excavation sites were required, they are restored to their original condition. This includes repairing any disturbed landscaping, driveways, or other features.

Benefits of CIPP Liners

CIPP liners offer several advantages over traditional pipe repair and replacement methods:

-

Minimal Disruption: One of the most significant benefits of CIPP liners is their minimal impact on the surrounding environment. Because the process is trenchless, it requires only small access points, reducing the need for extensive excavation. This makes CIPP lining ideal for urban areas, where disruption to roads, sidewalks, and other infrastructure can be a major concern.

-

Cost-Effectiveness: While the initial cost of CIPP liner installation may be higher than some traditional methods, it is often more cost-effective in the long run. The reduced need for excavation and restoration work helps lower overall project costs. Additionally, the durability and longevity of CIPP liners reduce the need for frequent repairs or replacements.

-

Durability and Longevity: CIPP liners are designed to be highly durable and resistant to corrosion, chemicals, and other environmental factors. The seamless nature of the liner eliminates joints and connections where problems can occur, providing a long-lasting solution to pipe repair.

-

Quick Installation: The trenchless nature of CIPP lining allows for faster installation compared to traditional methods. The entire process, from inspection to final restoration, can often be completed in a shorter timeframe, minimizing the disruption to property owners and reducing downtime.

-

Versatility: CIPP liners can be used to rehabilitate a wide range of pipe materials, including clay, cast iron, PVC, and concrete. This versatility makes CIPP lining suitable for various applications, from residential sewer lines to large municipal pipelines.

-

Improved Flow Capacity: The smooth, seamless surface of the CIPP liner can improve the flow capacity of the repaired pipe. By eliminating rough spots, joints, and other obstructions, the liner helps ensure efficient and uninterrupted flow of wastewater or other materials.

Applications of CIPP Liners

CIPP liners are used in a variety of applications, including:

-

Sewer and Drain Lines: CIPP lining is commonly used to repair and rehabilitate residential and municipal sewer and drain lines. The technology effectively addresses issues such as root intrusion, corrosion, and pipe cracks, restoring the functionality of the system.

-

Water Mains: In addition to sewer lines, CIPP liners are also used for water mains. The process can rehabilitate aging or damaged water pipes, ensuring a reliable supply of clean water.

-

Industrial Pipelines: CIPP lining is suitable for industrial pipelines that transport various materials, including chemicals and wastewater. The technology provides a durable and corrosion-resistant lining that enhances the longevity of the pipes.

-

Stormwater Pipes: CIPP liners can be used to rehabilitate stormwater pipes, helping to prevent blockages and maintain proper drainage. This is particularly important in areas prone to heavy rainfall or flooding.

Choosing the Right CIPP Liner

Selecting the appropriate CIPP liner for your project involves considering several factors:

-

Pipe Material: The type of pipe being repaired will influence the choice of CIPP liner material. Different resins and liners are available for various pipe materials, including clay, cast iron, PVC, and concrete.

-

Environmental Conditions: The environmental conditions in which the pipe is located will affect the choice of liner. Factors such as soil type, groundwater conditions, and exposure to chemicals should be considered when selecting a CIPP liner.

-

Pipe Size and Configuration: The size and configuration of the pipe being repaired will determine the appropriate liner dimensions and installation methods. CIPP liners are available in various sizes and can be customized to fit specific pipe dimensions.

-

Curing Method: The curing method used for the CIPP liner can impact the installation process and final results. Different curing methods, such as heat, steam, or UV light, have varying advantages and considerations.

-

Manufacturer and Quality: Choose a reputable manufacturer and ensure that the CIPP liner meets industry standards and quality requirements. High-quality liners will provide better performance and longevity.

Maintenance and Longevity of CIPP Liners

CIPP liners are designed to be low-maintenance and durable, but regular inspections and maintenance are still important to ensure their continued performance. Here are some tips for maintaining CIPP liners:

-

Regular Inspections: Schedule periodic inspections of the CIPP-lined pipes to check for any signs of issues or damage. Inspections can help identify potential problems early and prevent more serious issues from developing.

-

Avoiding Chemical Exposure: While CIPP liners are resistant to many chemicals, it is still important to avoid exposing the liner to harsh chemicals or substances that could potentially damage it. Follow guidelines for proper use and handling of chemicals.

-

Monitoring for Blockages: Keep an eye out for signs of blockages or reduced flow in the pipes. If issues arise, address them promptly to prevent damage to the liner and ensure continued proper function.

-

Preventive Maintenance: Implement preventive maintenance practices, such as proper waste disposal and avoiding items that could cause blockages, to help extend the life of the CIPP liner and the overall plumbing system.

Conclusion

CIPP liners represent a significant advancement in pipe rehabilitation technology, offering a versatile, durable, and efficient solution for repairing and maintaining pipes. By understanding the basics of CIPP liners, including their benefits, applications, and installation process, property owners, plumbers, and infrastructure managers can make informed decisions about their pipe repair and maintenance needs.

The trenchless nature of CIPP lining minimizes disruption, reduces costs, and provides a long-lasting repair solution. Whether addressing issues with sewer lines, water mains, or industrial pipelines, CIPP liners offer a reliable and effective approach to restoring pipe functionality and extending the lifespan of plumbing systems. As technology continues to evolve, CIPP liners will remain a valuable tool in the field of pipe rehabilitation, providing enduring benefits and contributing to the efficiency and reliability of modern infrastructure.

What's Your Reaction?