The Benefits of Inner Grooved Copper Tubes in Modern HVAC and Refrigeration Systems

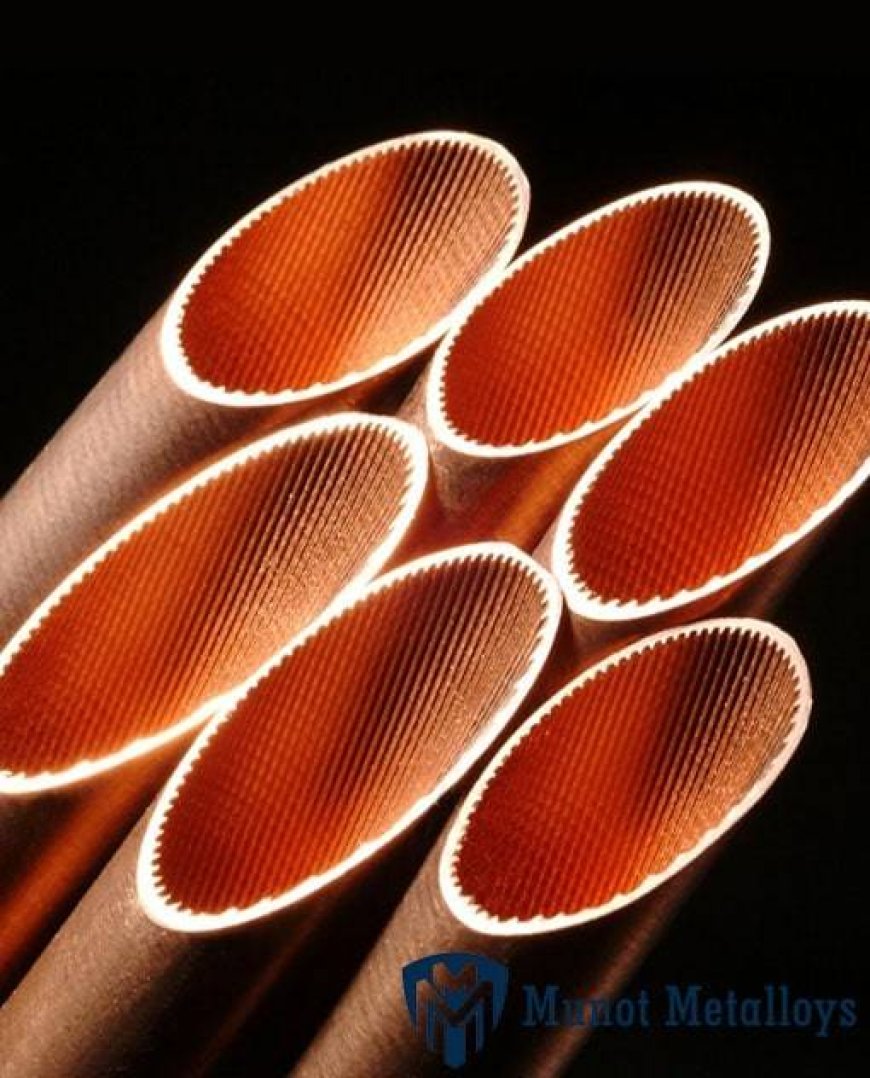

Inner Grooved Copper Tubes

What is an Inner Grooved Copper Tube?

An inner grooved copper tube is a type of copper tubing that has helical or spiral grooves on the inside surface of the tube. These grooves are engineered to increase the surface area within the tube, which enhances the efficiency of heat transfer. The concept behind the inner grooves is simple: by increasing the surface area in contact with the refrigerant or fluid passing through the tube, more heat can be transferred in a given period of time, improving overall system performance.

Inner grooved copper tubes are commonly used in applications like air conditioners, refrigeration units, and heat exchangers, where efficient heat exchange is critical to maintaining system performance and energy efficiency.

Key Features of Inner Grooved Copper Tubes

-

Increased Internal Surface Area: The most notable feature of inner grooved copper tubes is the increased surface area inside the tube due to the spiral grooves. This allows for better interaction between the refrigerant and the tube walls, resulting in more efficient heat transfer.

-

Enhanced Heat Transfer: The grooves create turbulence in the refrigerant flow, which helps in breaking the boundary layer of the refrigerant. This increases the overall heat transfer rate, making the system more efficient.

-

Compact Design: Because inner grooved tubes offer superior heat transfer capabilities, systems using these tubes can be designed to be smaller and more compact, reducing the overall size of HVAC and refrigeration units.

-

Lightweight: The improved efficiency means less material can be used for the same performance, making inner grooved copper tubes a lightweight option that contributes to the overall weight reduction of HVAC systems.

-

Durability and Corrosion Resistance: Like traditional copper tubing, inner grooved copper tubes are corrosion-resistant and highly durable. Copper’s natural resistance to corrosion ensures a longer life for the tubing, even in harsh environments.

How Inner Grooved Copper Tubes Work

The primary goal of inner grooved copper tubes is to improve the efficiency of heat transfer. Here’s how it works:

-

Increased Surface Area: The inner grooves significantly increase the surface area that comes in contact with the refrigerant or fluid inside the tube. This allows more heat to be absorbed or released by the refrigerant, improving heat transfer rates.

-

Turbulent Flow: The grooves create turbulence in the refrigerant flow. Normally, refrigerants flow in a smooth, laminar pattern inside the tube, which limits heat transfer. The grooves disturb this smooth flow, forcing the refrigerant into a more chaotic or turbulent flow. Turbulent flow improves the heat transfer process because it disrupts the boundary layer (the thin layer of fluid next to the tube walls), allowing for more efficient energy exchange.

-

Energy Efficiency: By enhancing heat transfer, inner grooved copper tubes allow HVAC and refrigeration systems to operate at lower energy levels while maintaining the same cooling or heating capacity. This reduces overall energy consumption, making systems more energy-efficient.

Benefits of Using Inner Grooved Copper Tubes

-

Improved Energy Efficiency: One of the primary benefits of inner grooved copper tubes is their ability to enhance energy efficiency. By improving heat transfer, these tubes allow HVAC systems and refrigeration units to consume less energy while providing the same level of cooling or heating. This translates to significant cost savings in energy bills, especially in large-scale operations.

-

Smaller System Size: The improved efficiency of inner grooved tubes means that manufacturers can design more compact HVAC and refrigeration systems without sacrificing performance. This is particularly beneficial for space-constrained environments, such as residential buildings or commercial spaces, where smaller systems are preferred.

-

Enhanced Cooling Capacity: Inner grooved copper tubes increase the cooling capacity of refrigeration systems, enabling them to handle larger cooling loads with improved efficiency. This is especially useful in commercial refrigeration, industrial freezers, and large-scale HVAC applications where heavy cooling is required.

-

Reduced Environmental Impact: With growing emphasis on energy efficiency and reducing carbon footprints, inner grooved copper tubes play a key role in creating environmentally friendly HVAC and refrigeration systems. By reducing energy consumption, these tubes help lower greenhouse gas emissions and contribute to global sustainability goals.

-

Long Lifespan: Like all copper products, inner grooved copper tubes are highly durable and resistant to corrosion. This ensures that they can withstand long-term use in various environments, reducing the need for frequent replacements and lowering maintenance costs over time.

-

Cost-Effective: Although inner grooved copper tubes may have a slightly higher upfront cost compared to standard tubes, their long-term energy savings and reduced maintenance costs make them a cost-effective investment in the long run.

Applications of Inner Grooved Copper Tubes

-

Air Conditioners: Inner grooved copper tubes are widely used in air conditioning systems to improve heat transfer and cooling efficiency. They are commonly found in both residential and commercial air conditioning units.

-

Refrigeration Systems: These tubes are essential in refrigeration systems where efficient cooling is required. Commercial refrigeration, industrial freezers, and domestic refrigerators all benefit from the enhanced performance provided by inner grooved copper tubes.

-

Heat Exchangers: In heat exchanger applications, where efficient heat transfer is paramount, inner grooved copper tubes ensure optimal energy exchange between fluids, improving the overall performance of the system.

-

Automotive Air Conditioning: The automotive industry has also adopted inner grooved copper tubes for use in vehicle air conditioning systems. Their lightweight, compact nature makes them perfect for enhancing the efficiency of car cooling systems.

-

Heat Pumps: Heat pumps that rely on effective heat transfer to provide heating or cooling also benefit from the use of inner grooved copper tubes, which ensure better performance and lower energy consumption.

Conclusion

Inner grooved copper tubes represent a significant leap in HVAC and refrigeration technology, offering improved heat transfer efficiency, energy savings, and system performance. Their ability to enhance cooling and heating capacity while reducing the size and energy consumption of systems makes them a valuable asset in today’s drive toward energy-efficient, sustainable technologies.

What's Your Reaction?