The Benefits Of Outsourcing PCB Manufacturing

Printed Circuit Boards (PCBs) are at the heart of modern electronic devices, connecting and powering components such as microprocessors, memory chips, sensors, capacitors, and connectors. These components are important for smartphones, medical equipment, and industrial machines. PCB production's intricate and precise nature makes it highly specialized and resource-intensive. For many businesses, turning to a PCB contract manufacturer is a strategic decision with many benefits. Here's a closer look at why outsourcing PCB manufacturing is beneficial.

Cost Efficiency

Manufacturing PCBs in-house requires substantial investment in equipment, infrastructure, and labor. PCB production and testing machinery is expensive and needs frequent updates to stay competitive. By outsourcing to a PCB assembly manufacturer, businesses can avoid these large capital expenses. Instead, they pay for services as needed, turning fixed costs into variable ones. This benefits small- to medium-sized companies that cannot afford the hefty investment needed for in-house production.

A PCB manufacturer also often operates on a much larger scale than individual companies could achieve on their own. With high-volume production capabilities, they can lower the cost per unit, benefiting their clients with more competitive pricing. Additionally, their access to bulk pricing for raw materials and components drives down overall manufacturing costs. Businesses can leverage these savings and redirect funds to other areas, such as R&D or marketing, by partnering with a contract manufacturer.

Access To Advanced Technology And Expertise

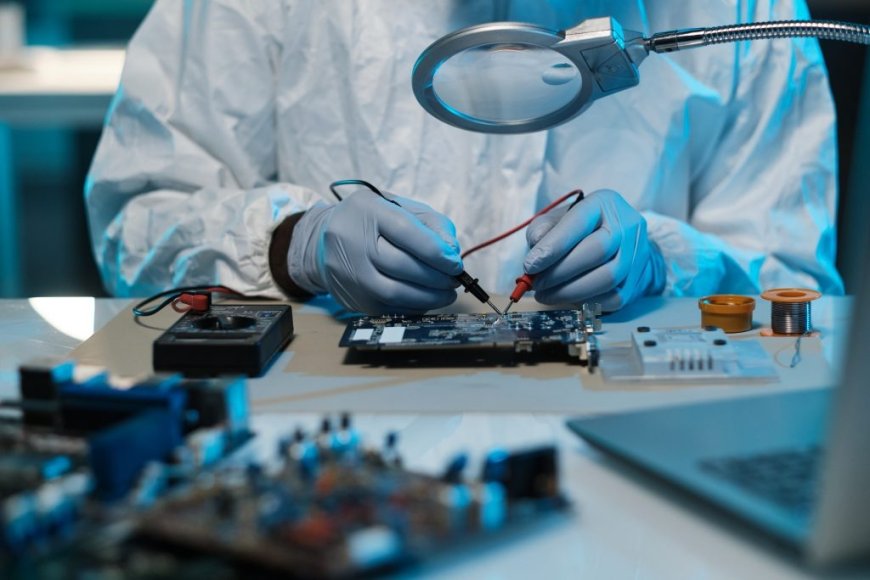

Many businesses find it challenging to keep up with technological advances in PCB manufacturing. Specialized PCB assembly manufacturers have state-of-the-art facilities with the latest production technologies, including automated assembly lines, advanced testing equipment, and sophisticated inspection systems. Outsourcing allows businesses to benefit from these high-end capabilities without investing in the equipment themselves.

PCB contract manufacturers also bring decades of experience and specialized expertise to the table. Their staff often includes seasoned engineers, designers, and quality control specialists who understand every aspect of PCB production. Working with these experts ensures that products are manufactured to specifications, with optimized designs and thorough testing. This collaboration can improve product quality, reduce errors, and speed up development.

Faster Time To Market

With how competitive today’s market is, time to market can make or break a product’s success. Experienced PCB manufacturers understand how to streamline production and cut down on delays. By offering efficient prototyping, rapid iterations, and optimized workflows, they help businesses meet market demands and deadlines. A faster production cycle means that businesses can introduce new products and stay ahead of the competition.

Markets are also unpredictable, with fluctuating demand and shifting priorities. A PCB contract manufacturer offers the flexibility to quickly scale production up or down, depending on current market demands. This adaptability minimizes production delays and helps align product launches with market opportunities.

Enhanced Quality And Reliability

Quality is a top priority in PCB manufacturing, as even a small flaw can lead to product failure. Contract manufacturers adhere to stringent quality control protocols, with inspections and testing at every production stage. Adhering to industry standards and certifications ensures that the final product is reliable and safe. Partnering with a dedicated PCB assembly manufacturer means benefiting from these rigorous processes and enhancing product quality.

These manufacturers also use manual and automated testing methods to verify performance, durability, and reliability. Functional testing, x-ray inspections, and environmental stress testing are just some of the meticulous checks performed. This reduces the risk of defects and product recalls.

Focus On Core Competencies

Outsourcing PCB manufacturing frees businesses to concentrate on what they do best: product design, marketing, or customer support. By delegating complex manufacturing tasks to experts, companies can reduce their internal workload and focus their resources on innovation, strategic initiatives, and growing their market presence.

Supply Chain Management Benefits

Managing the supply chain for PCB manufacturing involves sourcing components, managing inventory, and ensuring timely delivery. A PCB contract manufacturer can handle these logistics, reducing the complexity for their clients. This minimizes supply chain disruptions and improves production efficiency.

Contract manufacturers have also established relationships with suppliers worldwide. This global reach allows for competitive sourcing of high-quality components, driving down costs and ensuring timely material availability.

Conclusion

Outsourcing PCB manufacturing offers cost savings, improved quality, faster market entry, and strategic focus. Partnering with a PCB assembly manufacturer provides advanced technology, expertise, and efficiency, helping businesses stay competitive and innovative.

What's Your Reaction?