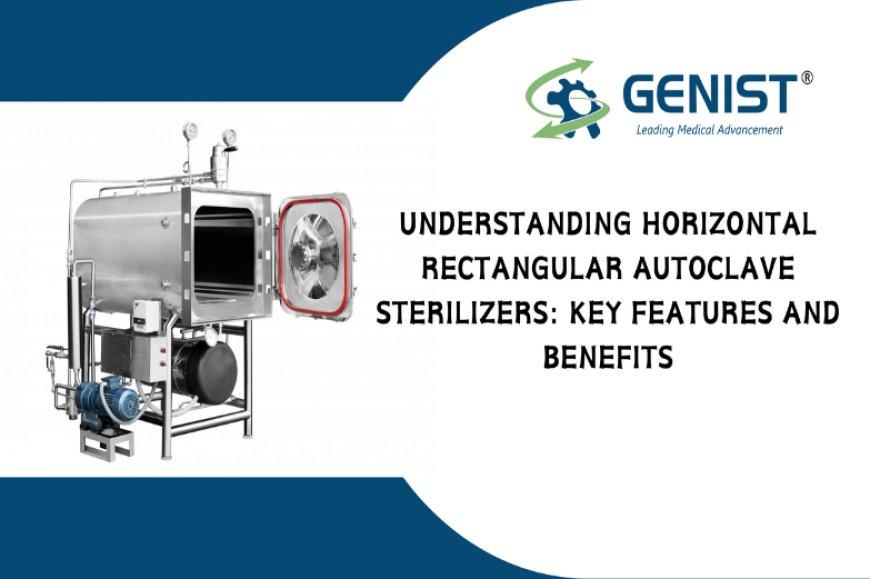

Understanding Horizontal Rectangular Autoclave Sterilizers: Key Features and Benefits

Explore the essentials of horizontal rectangular autoclave sterilizers. Understand their sturdy design, efficient steam sterilization, safety features, and customizable options, perfect for medical and industrial use.

In the medical and laboratory fields, sterilization is a critical process that ensures the safety and efficacy of instruments and materials. One of the most reliable and efficient sterilization methods is the use of autoclaves, particularly those designed by a leading Horizontal Rectangular Autoclave Sterilizer Manufacturer.

These sturdy machines designed to sterilize various types of equipment with powerful steam. Let's examine these unique autoclave sterilizers — their features, how they're designed, and what makes them beneficial.

What is a Horizontal Rectangular Autoclave Sterilizer?

This device gets used in labs, hospitals, and industries. Its job? Cleaning instruments, glass stuff, and more. The horizontal layout lets it hold a lot of load. So it's perfect for places that need many bulky things cleaned at once.

These equipment produces steam at intense pressure. This wipes out all harmful bacteria, viruses, fungi, and spores. The box-like rectangular design of the chamber makes the most of the inside space. It makes arranging things better during the sterilization.

Construction and Design

Horizontal rectangular autoclave sterilizers are built with durability and efficiency in mind. Their robust construction features an all-welded design that ensures leakproof operation—an essential factor in maintaining consistent sterilization performance.

Chamber and Jacket

The inner core of an autoclave is built with a heavy plate using sturdy, mild steel and a lining of non-magnetic stainless steel, either 304 or 316 grade. Why? This helps it fight rust and endure scorching temperatures and intense pressure during sterilization. Wrapped around its chamber is a jacket crafted from rolled steel. Its innovative design helps keep the steam spread consistently around the chamber.

Single Door Construction

Most horizontal rectangular autoclave sterilizers come with a single door made from rolled steel, lined with stainless steel on both sides. This construction not only provides durability but also ensures that the door can withstand the intense pressure and heat generated during the sterilization cycle. The door is hydraulically tested to endure up to 2.5 times the working pressure, ensuring safety and reliability during operation.

Insulation and Heat Retention

In order to stop heat from escaping, the steam jacket is lined on the outer side with insulating materials. These materials could be asbestos sheet or glass wool. These materials block heat from radiating, lifting the sterilizer's overall efficiency. The system is wrapped in a robust rolled steel sheet. Often, it is painted to guard against outside weather conditions.

Boiler and Heating System

The boiler plays a key part in the horizontal rectangular autoclave sterilizer. It's the maker of the vital steam needed for sterilizing things. It's built of thick stainless steel and smartly placed under the sterilizer. This spot is perfect for saving space and boosting efficiency.

Flanged-style, quality heating elements are installed at the boiler's front, giving easy reach during fix-ups or upkeep. The boiler comes with needed safety features, such as a water gauge glass to keep tabs on water amount, a safety valve, and inlet and outlet valves. It also has a low water level cut-off tool to keep the heating elements safe from burn-out due to dry running.

Safety Features

Safety is a paramount concern in the design of horizontal rectangular autoclave sterilizers. Each unit is equipped with a self-locking safety door, which cannot be opened while the chamber is under pressure. This feature ensures that operators are protected from accidental exposure to high-pressure steam.

Furthermore, the sterilizer is fitted with triple safety mechanisms, including a vacuum breaker, to prevent the formation of a vacuum during steam condensation. This feature is essential for maintaining the integrity of the sterilization process and ensuring that all materials within the chamber are properly sterilized.

Advanced Options

If you need more advanced features, you can upgrade horizontal rectangular autoclave sterilizers. You can use a PLC (Programmable Logic Controller) instead of the normal digital controller. The PLC gives you better control of the sterilization process. This makes the sterilization process more efficient and reliable. If needed, there is also a double-door option. This is great for places that need a pass-through design. It makes work easier in sterile conditions.

Conclusion

Choosing a reliable horizontal rectangular autoclave sterilizer manufacturer is crucial to ensure that your facility has the best possible sterilization equipment. Horizontal rectangular autoclave sterilizers are indispensable in settings where reliable and efficient sterilization is critical. Their robust construction, advanced safety features, and customizable options make them an ideal choice for laboratories, hospitals, and industrial applications.

By getting the above knowledge on the main parts and perks of these sterilizing machines, you can better choose the best product for your sterilizing needs. Teaming up with a reputable scientific equipment manufacturer means you'll get products that meet all your top quality and safety requirements.

What's Your Reaction?

![Fairy Farms Hemp Gummies Australia [I've Tested] TRUTH EXPOSED!](https://news.bangboxonline.com/uploads/images/202412/image_430x256_6760162cde80e.jpg)