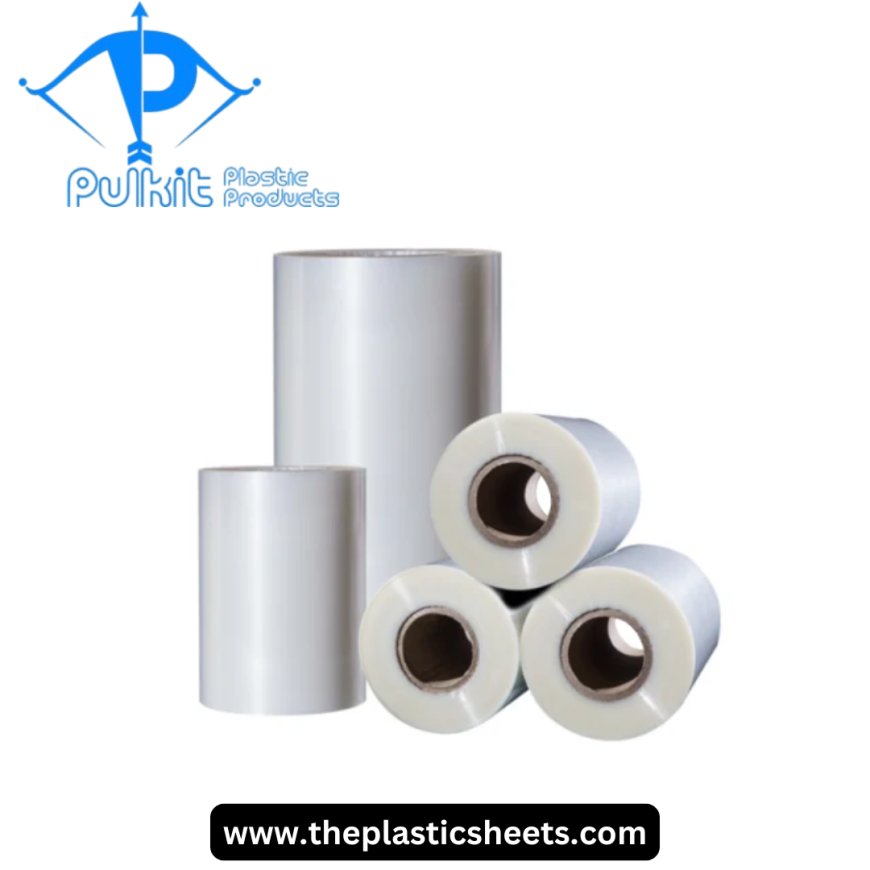

Understanding PE Film: Uses, Benefits, and the Market Landscape

Introduction to PE Film

Polyethylene (PE) film is a widely-used and versatile packaging material derived from ethylene, a byproduct of natural gas or petroleum. Renowned for its excellent protective qualities, this film is employed across various industries, ranging from agriculture to food packaging and industrial applications. The characteristics of PE film, such as its durability, flexibility, and impermeability to moisture, have led to a surge in demand among manufacturers and consumers alike. As the market for Pulkit Plastic Products continues to grow, understanding its applications and the roles of PE film suppliers and manufacturers becomes crucial.

Types and Applications of PE Film

There are several types of PE film, each designed for specific applications. The most common are Low-Density Polyethylene (LDPE) and High-Density Polyethylene (HDPE). LDPE film is known for its flexibility, making it ideal for applications such as plastic bags, shrink wraps, and flexible packaging for consumer goods. In contrast, HDPE film is more rigid and resistant to punctures, making it suitable for industrial applications, including vapor barriers and heavy-duty bags. PE film is widely used in agriculture for greenhouse coverings, mulch films, and silage bags, providing the protection crops need from environmental factors. Its ability to resist moisture makes it particularly valuable in areas like food storage, where it prevents spoilage and extends shelf life.

Benefits of Using PE Film

One of the defining features of PE film manufacturers is its outstanding moisture resistance. This property helps protect products during transportation and storage, especially in humid environments. Additionally, PE film is lightweight, which reduces shipping costs and makes it easier to handle. Its flexibility allows for a consistent, tight seal, ensuring that products are securely packaged. Moreover, PE film is recyclable, aligning with an increasing emphasis on sustainability within the packaging industry. As companies and consumers alike become more environmentally conscious, the ability to recycle PE film offers an appealing solution to product packaging waste.

The Role of PE Film Manufacturers

PE film manufacturers play a vital role in the production and distribution of this versatile material. They utilize advanced extrusion and processing techniques to create films that meet various industry standards and tailored specifications. These manufacturers can cater to a wide range of needs, from creating custom thicknesses and colors to incorporating additives that enhance performance characteristics such as UV resistance and anti-fog properties. Collaborations between PE film manufacturers and businesses seeking specific solutions contribute to the innovation and evolution of packaging products, further expanding the versatility and usability of PE film in various sectors.

The Supply Chain of PE Film

The supply chain for PE film manufacturer involves several key players, including raw material suppliers, manufacturers, converters, and distributors. To create high-quality PE film, manufacturers rely on a steady supply of polyethylene resin, typically sourced from petrochemical plants. Once the raw material is acquired, manufacturers use extrusion techniques to create film rolls, which can then be cut and printed according to client specifications. After production, converters further process the film into finished products, such as bags, packaging materials, or agricultural films. Distributors then play a crucial role in getting these products to end-users, such as grocery retailers, agricultural businesses, and industries in need of durable packaging solutions.

Global Market Trends and Insights

The global PE film market has experienced significant growth over the past decade, driven by the increasing demand for flexible packaging solutions across various industries. In sectors like food and beverages, the need for high-quality protective packaging has escalated as consumers demand fresher products with longer shelf lives. Additionally, the rise in e-commerce has led to greater demand for efficient packaging solutions, further propelling the growth of PE film suppliers. Market analysts project a positive growth trajectory for the PE film industry, with innovations focusing on sustainability, biodegradable alternatives, and enhanced functional properties shaping its future.

Challenges Facing PE Film Manufacturers

Despite the market's growth, PE film manufacturers face several challenges. One of the most significant hurdles is the environmental impact associated with plastic use and disposal. While PE film is recyclable, the recycling rates remain low, prompting pressure for sustainable alternatives. Manufacturers are increasingly tasked with developing eco-friendly practices and materials that align with shifting consumer preferences towards sustainability. Furthermore, fluctuations in the costs of raw materials can also impact profitability and market stability for PE film manufacturers. As these challenges arise, the industry must adapt by embracing innovation and sustainable practices to remain competitive.

Conclusion

The PE film suppliers has established itself as a cornerstone of modern packaging, offering extensive versatility and protective benefits across various industries. With the growing demand for sustainable and efficient packaging solutions, PE film suppliers and manufacturers play a crucial role in delivering quality products that meet the evolving needs of their customers. As the industry transitions towards more sustainable practices, the development of eco-friendly alternatives and enhanced functionalities will dictate the future of PE film. Understanding the landscape of PE film—from its applications to the roles of manufacturers and suppliers—will be essential for businesses that seek to leverage this vital material.

Frequently Asked Questions

-

What types of PE film are available in the market?

The two main types of PE film are Low-Density Polyethylene (LDPE) and High-Density Polyethylene (HDPE), each suited for specific applications such as flexible packaging and industrial uses. -

How can I recycle PE film?

PE film can often be recycled through designated drop-off locations or programs in many communities. It’s important to check local recycling guidelines, as not all facilities accept PE film. -

What industries benefit most from using PE film?

Industries such as food and beverage, agriculture, and e-commerce benefit significantly from PE film due to its moisture resistance, flexibility, and lightweight properties. -

Why is the sustainability of PE film a concern?

The sustainability of PE film is a concern due to issues with plastic waste and low recycling rates. The industry faces pressure to innovate and produce more eco-friendly alternatives to traditional plastics.

What's Your Reaction?