Use of Inner Grooved Copper Tubes in Various Industries

Copper tubes have long been celebrated for their excellent thermal conductivity, durability, and versatility. Among the many innovations in copper tube technology, inner grooved copper tubes have emerged as a key player in enhancing efficiency across various industries. This article explores the use of inner grooved copper tubes in different sectors, highlighting their advantages and specific applications. Additionally, we will touch upon the role of Copper Plain LWC for ACR (Air Conditioning and Refrigeration) applications and how it complements the performance of inner grooved copper tubes.

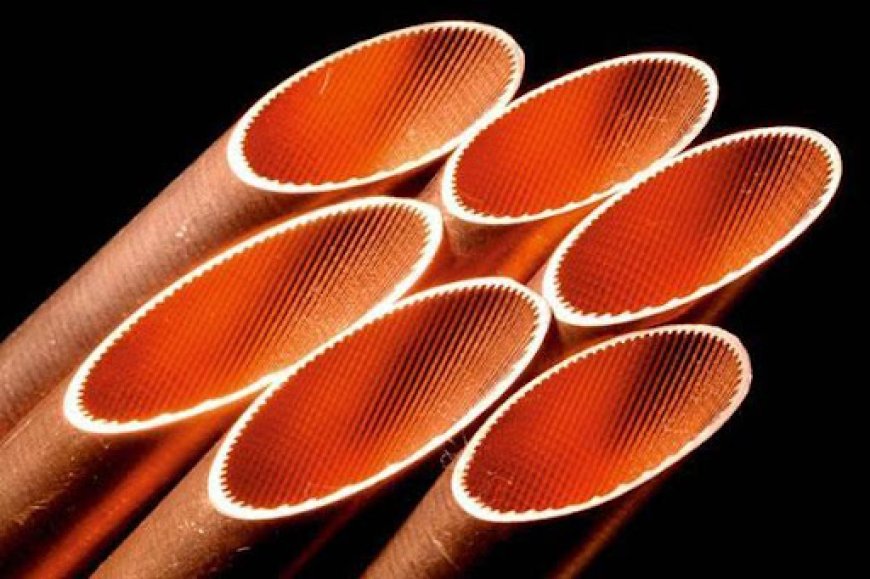

Understanding Inner Grooved Copper Tubes

1. What Are Inner Grooved Copper Tubes? Inner grooved copper tubes feature internal grooves or ribs that run longitudinally along the tube’s inner surface. These grooves increase the surface area for heat exchange, leading to enhanced thermal performance. This design modification allows for improved heat transfer rates and better refrigerant flow compared to standard smooth copper tubes.

2. Key Advantages

- Enhanced Heat Transfer: The grooves inside the tube create turbulence in the refrigerant flow, improving heat transfer efficiency.

- Reduced Energy Consumption: Improved thermal performance translates into reduced energy requirements for cooling or heating processes.

- Compact Design: Greater heat transfer efficiency allows for more compact and lightweight designs, which are beneficial in space-constrained applications.

Applications of Inner Grooved Copper Tubes

1. HVAC Systems In HVAC (Heating, Ventilation, and Air Conditioning) systems, inner grooved copper tubes play a crucial role in enhancing heat exchangers and evaporators. The improved heat transfer efficiency helps HVAC systems achieve better cooling performance and reduced energy consumption. By using inner grooved copper tubes, HVAC systems can operate more efficiently, leading to cost savings and extended equipment lifespan.

2. Refrigeration The refrigeration industry benefits significantly from the use of inner grooved copper tubes. These tubes are used in various components, including condensers and evaporators, where efficient heat exchange is essential. The enhanced performance of inner grooved copper tubes leads to more effective refrigeration processes, reduced energy usage, and improved cooling capacity.

3. Automotive Industry In the automotive sector, inner grooved copper tubes are used in radiators and air conditioning systems. The improved thermal performance helps in efficient cooling of engine components and enhances the overall comfort within the vehicle. The ability to manage heat effectively contributes to better engine performance and fuel efficiency.

4. Industrial Heat Exchangers Industrial heat exchangers, used in applications ranging from chemical processing to power generation, benefit from the enhanced thermal performance of inner grooved copper tubes. The grooves inside the tubes facilitate more efficient heat transfer, which is crucial for maintaining optimal operating conditions in various industrial processes.

5. Building and Construction In building and construction, inner grooved copper tubes are used in plumbing and heating systems. Their enhanced thermal efficiency ensures effective heat distribution in radiant heating systems and improves the overall performance of hot water systems. The durability of copper tubes also ensures long-lasting and reliable service in construction applications.

Copper Plain LWC for ACR Applications

1. What Is Copper Plain LWC? Copper Plain LWC (Low Wall Copper) is a type of copper tube designed specifically for Air Conditioning and Refrigeration (ACR) applications. It features a low wall thickness, which makes it lightweight and flexible while maintaining good thermal conductivity.

2. Complementary Role with Inner Grooved Copper Tubes Copper Plain LWC complements the performance of inner grooved copper tubes in ACR applications. While inner grooved copper tubes enhance heat transfer efficiency, Copper Plain LWC provides flexibility and ease of installation in confined spaces. Together, they offer a comprehensive solution for optimizing heat exchange and system performance in air conditioning and refrigeration systems.

3. Applications in ACR Systems In ACR systems, Copper Plain LWC is used alongside inner grooved copper tubes in components such as evaporators and condensers. The combination of these tubes ensures efficient cooling and heating, contributes to energy savings, and enhances the overall reliability of the system.

Conclusion

Inner grooved copper tubes represent a significant advancement in tube technology, offering enhanced heat transfer efficiency and reduced energy consumption across various industries. From HVAC systems and refrigeration to automotive and industrial heat exchangers, these tubes provide superior performance and reliability.

In Air Conditioning and Refrigeration applications, the combination of inner grooved copper tubes with Copper Plain LWC delivers optimal heat exchange, flexibility, and efficiency. By understanding the unique benefits and applications of these technologies, industries can make informed decisions and achieve better performance in their systems.

What's Your Reaction?