What is the Difference Between Titanium Grade 2 Round Bars and Titanium Grade 12 Round Bars?

Discover the key differences between Titanium Grade 2 and Grade 12 round bars in terms of corrosion resistance, strength, and applications. Choose the right titanium grade for your project with insights from our comprehensive comparison.

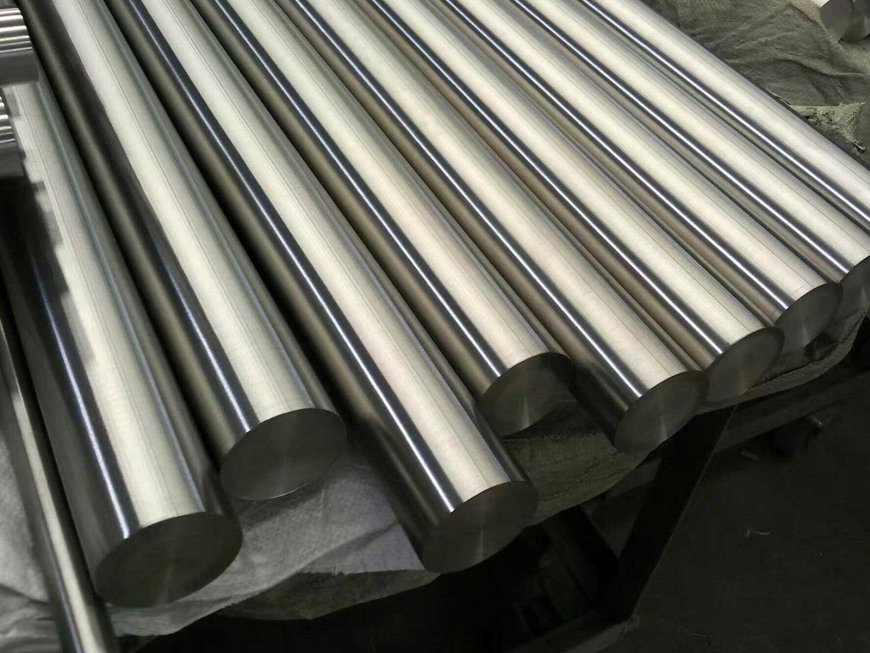

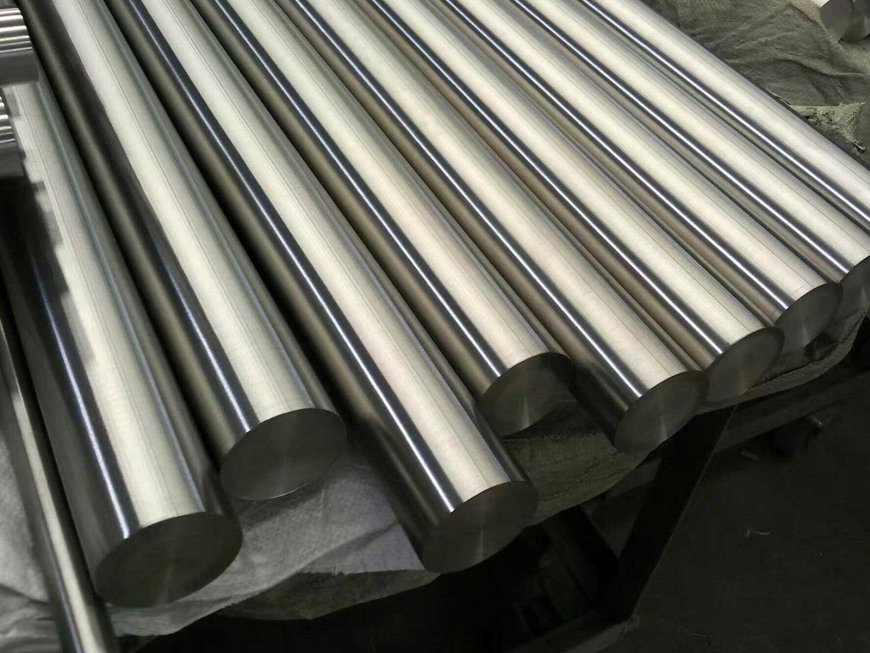

Titanium is a versatile and highly sought-after material in various industries due to its exceptional strength, lightweight nature, and impressive resistance to corrosion. Among the many grades of titanium available, Titanium Grade 2 Round Bars and Titanium Grade 12 Round Bars are particularly popular. Although they share some similarities, each grade offers unique properties that make them suitable for different applications. In this blog, we will explore the differences between these two types of titanium round bars to help you make an informed decision for your specific needs.

Titanium Grade 2 Round Bars

Characteristics

Titanium Grade 2 Round Bars are made from commercially pure titanium, typically containing around 99.2% titanium. This grade is known for its excellent balance of strength, ductility, and corrosion resistance. Some of the key properties include:

-

Corrosion Resistance: Grade 2 titanium is highly resistant to corrosion in various environments, including seawater, chlorides, and acids. This makes it ideal for marine, chemical, and desalination applications.

-

Strength-to-Weight Ratio: With a good strength-to-weight ratio, Grade 2 titanium is lightweight yet strong, making it suitable for aerospace and automotive industries.

-

Weldability and Formability: Grade 2 titanium is easily weldable and formable, allowing for versatile manufacturing processes and the creation of complex shapes and structures.

Applications

Due to its versatile properties, Titanium Grade 2 Round Bars are used in a wide range of applications, such as:

-

Marine environments (e.g., shipbuilding, offshore structures)

-

Chemical processing equipment

-

Desalination plants

-

Aerospace components

-

Medical devices and implants

Titanium Grade 12 Round Bars

Characteristics

Titanium Grade 12 Round Bars are an alloy of titanium that includes small amounts of nickel (0.6% to 0.9%) and molybdenum (0.2% to 0.4%). This grade offers enhanced properties compared to commercially pure titanium, making it suitable for more demanding applications. Key properties include:

-

Corrosion Resistance: The addition of nickel and molybdenum provides Titanium Grade 12 Round Bars with superior resistance to corrosion, especially in highly acidic environments and at elevated temperatures.

-

Enhanced Strength: Grade 12 titanium offers higher strength than Grade 2, making it suitable for applications where additional mechanical properties are required.

-

Thermal Stability: With better thermal stability, Grade 12 titanium performs well under high-temperature conditions, making it ideal for chemical processing and power generation industries.

Applications

Titanium Grade 12 Round Bars are used in applications that require superior corrosion resistance and strength, such as:

-

Chemical processing plants (e.g., heat exchangers, pressure vessels)

-

Power generation equipment

-

Offshore oil and gas platforms

-

Industrial equipment exposed to aggressive environments

Conclusion

Titanium Grade 2 Round Bars and Titanium Grade 12 Round Bars offer unique advantages that make them suitable for specific applications. Grade 2 titanium is an excellent choice for applications requiring a good balance of strength, corrosion resistance, and formability. On the other hand, Grade 12 titanium provides superior corrosion resistance and enhanced strength, making it ideal for more demanding environments and applications. Understanding the differences between these two grades will help you select the right material for your project, ensuring optimal performance and longevity.

What's Your Reaction?

![Nitric Boost Ultra: [TOP 5 Reasons!] Why We’re Your Best Choice?](https://news.bangboxonline.com/uploads/images/202412/image_430x256_676e98f0b0915.jpg)

![Nitric Boost Ultra Reviews – [Price UPDATED 2024] Your Key to Explosive Power](https://news.bangboxonline.com/uploads/images/202412/image_430x256_676e94350e710.jpg)

![LeanCaps Suppléments [LeanCaps Avis] Pour La Gestion Du Poids - Stimuler Le Métabolisme, Stimuler L'énergie](https://news.bangboxonline.com/uploads/images/202412/image_430x256_676f9e4140bdc.jpg)