Why High-Performance Slitter Cutters Matter in Industrial Production

Slitter cutters play a crucial role in industrial production, ensuring precise and efficient cutting of materials like paper, plastic, metal, and textiles. High-performance slitter cutters can significantly impact productivity, product quality, and operational efficiency. Investing in top-quality slitter cutters is essential for industries looking to maximize output and minimize downtime.

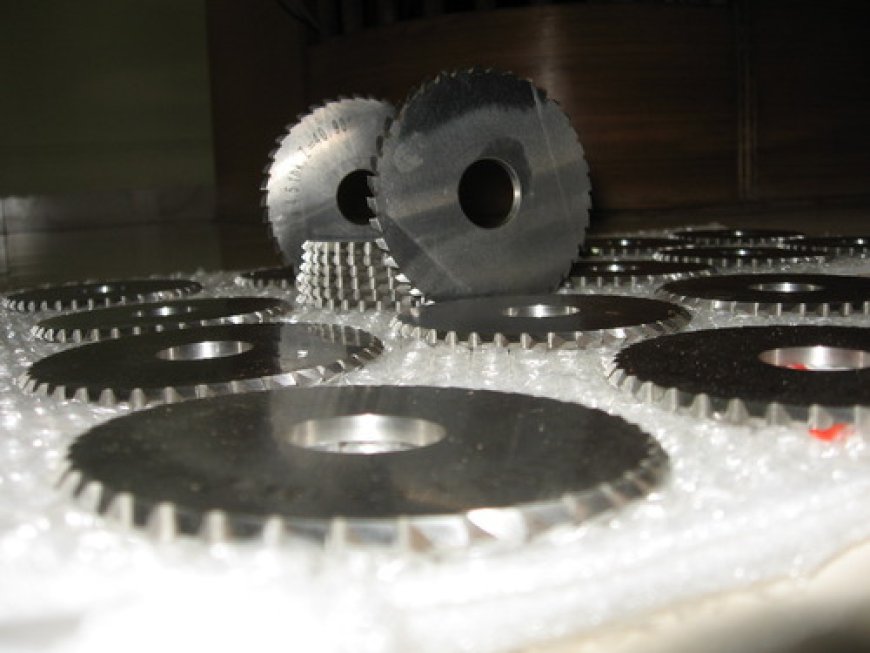

Importance of High-Performance Slitter Cutters

1. Precision Cutting for Superior Quality

Industries demand high accuracy in cutting processes to maintain product consistency. High-performance slitter cutters provide clean, precise cuts, reducing material waste and enhancing product quality. Whether used in packaging, automotive, or textile industries, precision cutting ensures smooth operations and satisfied customers.

2. Enhanced Durability and Longevity

Low-quality slitter cutters wear out quickly, leading to frequent replacements and increased maintenance costs. High-performance slitter cutters, like those from Maxwell Slitters, are made from premium materials such as carbide or high-speed steel, ensuring extended blade life and durability. These cutters withstand high-speed operations and tough materials, reducing downtime and increasing efficiency.

3. Increased Production Efficiency

Using high-quality slitter cutters improves production speed without compromising accuracy. Efficient cutting tools help manufacturers process large volumes of materials faster, boosting productivity and reducing operational costs. This is particularly important in industries where time-sensitive production is critical, such as paper conversion and flexible packaging.

4. Minimized Material Waste

Precision cutting tools ensure minimal material wastage by producing cleaner cuts. Poor-quality cutters can lead to rough edges, uneven cuts, and excessive scrap material. High-performance slitter cutters optimize material usage, leading to cost savings and improved sustainability in industrial processes.

5. Reduced Machine Downtime

Frequent blade changes and maintenance disruptions can slow down production lines. High-performance slitter cutters are designed to maintain sharpness for longer periods, reducing the need for constant replacements. This leads to less downtime and more consistent operation, ultimately benefiting the overall production cycle.

Choosing the Right Slitter Cutters

Selecting the right slitter cutter depends on factors such as material type, cutting speed, and application requirements. Here are some key considerations:

-

Blade Material: Opt for high-speed steel or tungsten carbide for durability.

-

Coating: Some blades come with coatings like titanium nitride for added strength.

-

Blade Edge Design: The type of edge (flat, serrated, or beveled) impacts cutting efficiency.

-

Compatibility: Ensure the cutter fits the specific slitting machine used in production.

Why Choose Maxwell Slitters?

Maxwell Slitters is a trusted name in the industry, providing high-performance slitter cutters designed for maximum precision, durability, and efficiency. Our slitter cutters are engineered using advanced technology and high-quality materials to meet the demands of industrial production. With a commitment to quality and customer satisfaction, Maxwell Slitters helps businesses optimize their cutting processes for better results.

Conclusion

High-performance slitter cutters are essential for industries that rely on precision cutting and efficient production. They enhance product quality, reduce waste, increase durability, and improve overall productivity. Investing in premium slitter cutters, such as those from Maxwell Slitters, ensures long-term benefits and a competitive edge in industrial production. Choose quality, choose efficiency—choose Maxwell Slitters for superior cutting solutions.

What's Your Reaction?